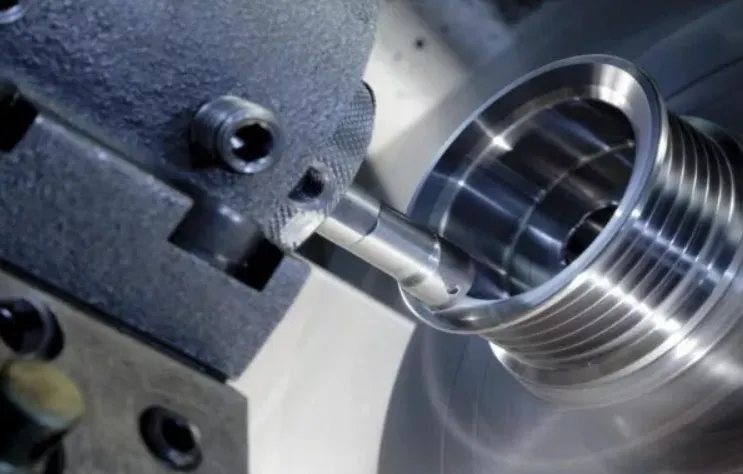

Boring machining is a precision technique primarily used to enlarge existing holes in a workpiece to achieve greater diameters and improved dimensional accuracy. As industries evolve, so do the technologies and methods employed in boring operations. Modern boring machines are highly sophisticated, often equipped with CNC (Computer Numerical Control) capabilities that enhance precision and repeatability. This innovation allows for complex geometries to be machined with minimal manual intervention, significantly increasing productivity.

One notable trend is the advancement of boring tools and heads, which are designed to maintain tighter tolerances and improve surface finishes. For instance, the use of indexable carbide inserts has become prevalent, enabling quick tool changes and reducing downtime during machining operations. Smart features such as real-time monitoring of tool wear and automatic tool compensation are also being integrated into boring machines, ensuring optimal performance and reducing the risk of defects.

One notable trend is the advancement of boring tools and heads, which are designed to maintain tighter tolerances and improve surface finishes. For instance, the use of indexable carbide inserts has become prevalent, enabling quick tool changes and reducing downtime during machining operations. Smart features such as real-time monitoring of tool wear and automatic tool compensation are also being integrated into boring machines, ensuring optimal performance and reducing the risk of defects.

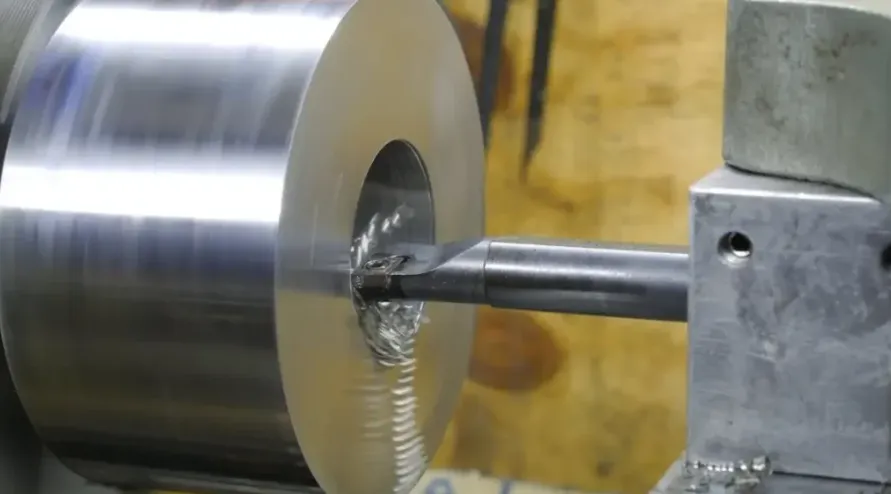

Moreover, the demand for deeper, more precise holes has led to the development of deep hole boring techniques. These techniques utilize specialized equipment that can handle the unique challenges presented by deep hole machining, such as chip removal and coolant delivery. Industries like aerospace, automotive, and medical manufacturing are driving this demand, necessitating higher precision and efficiency in creating complex parts.

Sustainability is another important consideration influencing boring technology today. Manufacturers are increasingly focused on reducing material waste and improving energy efficiency during machining processes. This has led to the adoption of eco-friendly cutting fluids and recyclable tooling materials, aligning industrial practices with environmental standards.

As boring technology continues to advance, the future looks promising, with continuous innovations paving the way for even higher precision and efficiency across various applications. The integration of automation and artificial intelligence into boring processes is expected to further enhance capabilities, allowing for adaptive machining strategies that react to real-time production data.