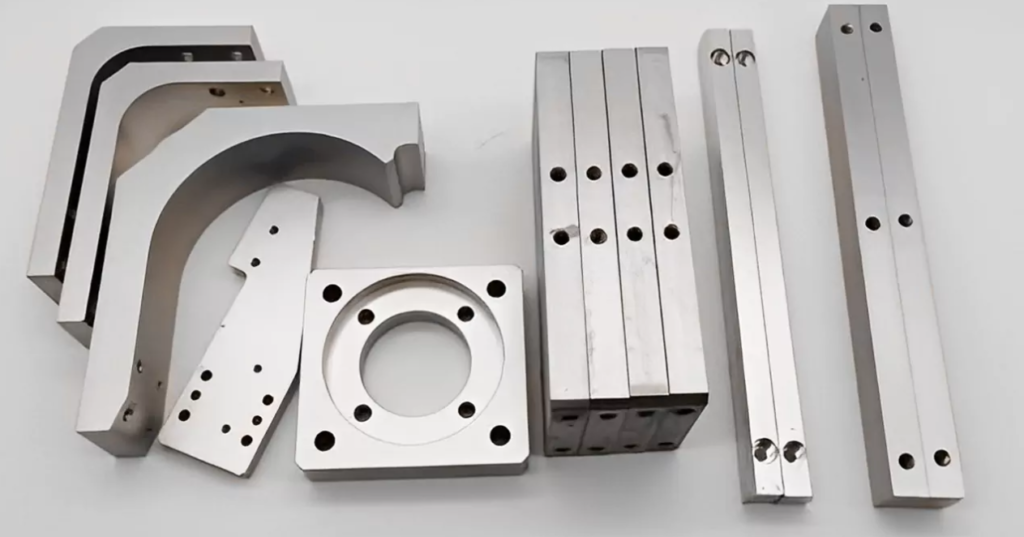

CNC (Computer Numerical Control) machining has revolutionized the manufacturing industry by providing unmatched precision, repeatability, and efficiency. CNC machining parts are widely used across industries such as aerospace, automotive, medical, and electronics due to their ability to meet tight tolerances and complex geometries. In this article, we will explore the key aspects of CNC machining parts, including materials, processes, tolerances, surface finishes, and quality control.

1. Common Materials Used in CNC Machining

CNC machining parts can be made from a variety of materials. The most commonly used materials include:

- Metals: Aluminum (6061, 7075), Stainless Steel (304, 316), Brass, Titanium, and Copper.

- Plastics: ABS, Nylon, PEEK, Delrin (Acetal), and Polycarbonate.

- Composites & Special Alloys: Carbon Fiber Reinforced Polymers (CFRP), Inconel, and Magnesium alloys.

The choice of material depends on factors like strength, weight, thermal resistance, and corrosion resistance.

2. CNC Machining Processes

CNC machining involves various subtractive manufacturing processes to create precise CNC machining parts:

- Milling: Uses rotating cutting tools to remove material from a workpiece. Suitable for complex 3D shapes and features like slots, pockets, and holes.

- Turning (Lathe Machining): The workpiece rotates while a cutting tool removes material, ideal for cylindrical parts.

- Drilling: Creates precise holes with different diameters and depths.

- EDM (Electrical Discharge Machining): Uses electrical sparks to machine hard materials and intricate features.

- Grinding: Ensures ultra-precise surface finishes and tight tolerances.

3. Tolerances and Precision in CNC Machining

One of the biggest advantages of CNC machining parts is their ability to achieve high precision. Typical tolerances range from ±0.005 mm to ±0.01 mm, depending on the material and machining process. High-precision applications, such as aerospace and medical devices, can demand tolerances as tight as ±0.002 mm.

4. Surface Finishing Options

CNC machining parts can be further enhanced with various surface finishing techniques:

- As-Machined: No additional finishing, but tool marks may be visible.

- Anodizing: Enhances corrosion resistance and adds color (common for aluminum parts).

- Powder Coating: A durable and aesthetically pleasing finish applied via electrostatic powder.

- Electropolishing: Used for stainless steel parts to improve corrosion resistance and appearance.

- Bead Blasting: Creates a smooth, matte texture by blasting fine media particles.

- Plating: Nickel or zinc plating adds extra protection against wear and corrosion.

5. Quality Control in CNC Machining

Quality control is a critical aspect of producing CNC machining parts to ensure accuracy and consistency. Some key inspection methods include:

- CMM (Coordinate Measuring Machine): Measures part dimensions with extreme accuracy.

- Laser Scanning: Captures detailed surface data for complex geometries.

- Microscopy & X-ray Inspection: Used for examining micro-defects and internal structures.

- Go/No-Go Gauges: Simple tools to quickly verify dimensional accuracy.

- First Article Inspection (FAI): A detailed report on initial production runs to validate the manufacturing process.

6. CNC Machining vs. Other Manufacturing Methods

While CNC machining parts offer high precision and versatility, it is essential to compare them with other manufacturing techniques:

| Manufacturing Method | Strengths | Weaknesses |

|---|---|---|

| CNC Machining | High precision, material versatility, low setup time | Higher material waste, costlier for large production |

| 3D Printing | Complex geometries, minimal material waste | Slower process, limited material strength |

| Injection Molding | Cost-effective for high volume, excellent surface finish | High upfront tooling costs |

| Die Casting | Ideal for mass production, good mechanical properties | Expensive molds, limited material options |

7. Applications of CNC Machining Parts

Due to their precision and durability, CNC machining parts are used in various industries:

- Aerospace: Aircraft engine components, structural parts, and landing gear.

- Automotive: Engine parts, transmission housings, and custom car modifications.

- Medical: Surgical tools, prosthetics, and orthopedic implants.

- Electronics: Heat sinks, enclosures, and precision connectors.

- Robotics: High-precision gears, frames, and actuators.

8. Future Trends in CNC Machining

The CNC machining parts industry continues to evolve with advancements in automation and digital integration:

- AI and Machine Learning: Optimizing tool paths and reducing waste.

- 5-Axis CNC Machining: Increasing the complexity and precision of parts.

- Hybrid Manufacturing: Combining CNC machining with 3D printing for enhanced efficiency.

- Smart Factories & IoT: Real-time monitoring of CNC machines for predictive maintenance.

Conclusion

CNC machining parts remain an indispensable part of modern manufacturing. Their ability to produce high-precision components with excellent repeatability makes them a top choice across various industries. As advancements in automation and smart manufacturing continue, CNC machining parts will only become more efficient and accessible. Whether you’re a business looking for reliable components or an engineer designing the next big innovation, CNC machining parts are a technology worth leveraging.