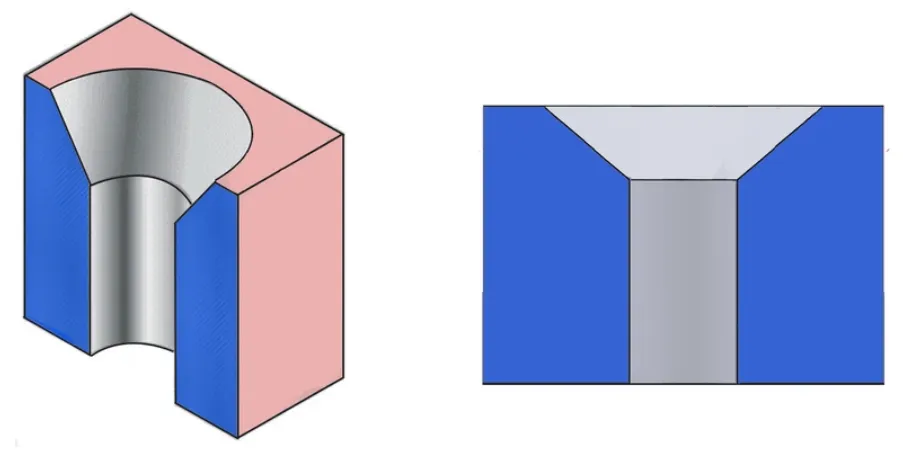

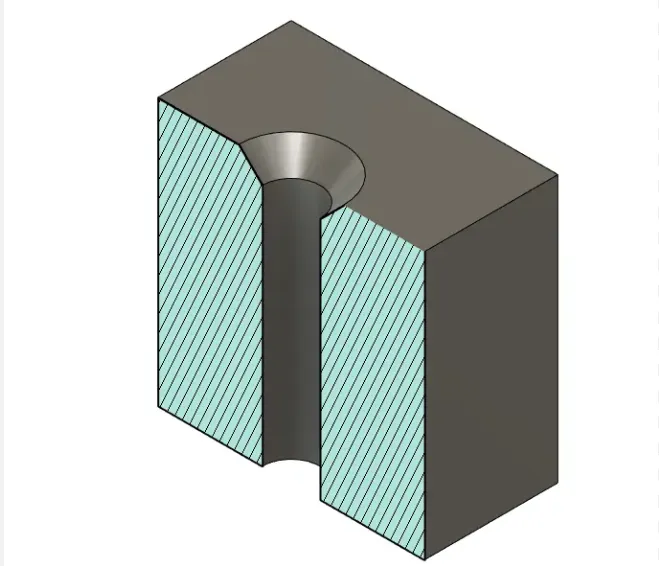

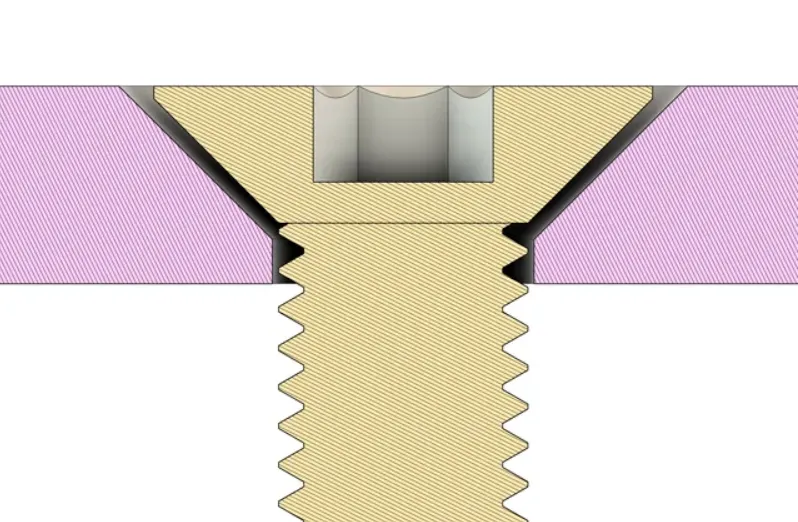

In mechanical design and manufacturing, countersunk holes represent a critical fastener solution where flush surface mounting is required. These conical recesses allow screw heads to sit perfectly level with or below the material surface, eliminating protrusions that could interfere with assembly or create safety hazards. The geometry follows strict standards, with typical included angles of 82°, 90°, or 100° matching common screw head angles – ANSI B18.6.3 specifies 82° for flat head screws in imperial sizes, while ISO 10664 standardizes 90° for metric applications.

Material science plays a crucial role in countersinking performance. When machining aluminum 6061-T6, carbide countersink tools maintain angle accuracy within ±0.5° for over 5,000 holes before requiring replacement. In contrast, stainless steel 304 demands cobalt-alloy tools with TiCN coatings, which sustain cutting edge integrity for approximately 1,200-1,500 holes at recommended speeds of 80-120 SFM (surface feet per minute). The aerospace industry often employs cryogenically treated tungsten carbide countersinks for titanium alloys, extending tool life by 300% compared to conventional tools when producing holes for flush rivets in wing skins.

Material science plays a crucial role in countersinking performance. When machining aluminum 6061-T6, carbide countersink tools maintain angle accuracy within ±0.5° for over 5,000 holes before requiring replacement. In contrast, stainless steel 304 demands cobalt-alloy tools with TiCN coatings, which sustain cutting edge integrity for approximately 1,200-1,500 holes at recommended speeds of 80-120 SFM (surface feet per minute). The aerospace industry often employs cryogenically treated tungsten carbide countersinks for titanium alloys, extending tool life by 300% compared to conventional tools when producing holes for flush rivets in wing skins.

Precision measurement ensures proper countersink dimensions. Modern optical comparators measure diameter within 0.01mm, while digital angle gauges verify cone angles to ±0.1°. In critical applications like aircraft structural components, profilometers map the entire conical surface, ensuring the 0.05mm maximum deviation allowed by ASME Y14.5 standards. The automotive sector has adopted automated vision systems that inspect 600+ countersunk holes per minute on transmission housings, rejecting any with burrs exceeding 0.1mm height.

Innovations in countersinking technology continue to emerge. Laser-assisted machining now creates burr-free countersinks in carbon fiber composites by locally heating the matrix before cutting. Hybrid drilling-countersinking tools with micro-lubrication channels can produce a perfect #10-32 UNC threaded hole with matching 82° countersink in A286 steel in one operation, reducing cycle times by 40%. For mass production, CNC machines equipped with force-feedback countersinking heads automatically compensate for tool wear, maintaining consistent depth within 0.02mm across 10,000+ cycles.

From consumer electronics to heavy machinery, countersunk holes remain an essential feature enabling sleek designs and reliable mechanical joints. Their continued evolution reflects the ongoing demand for precision in an increasingly miniaturized and performance-driven manufacturing world.