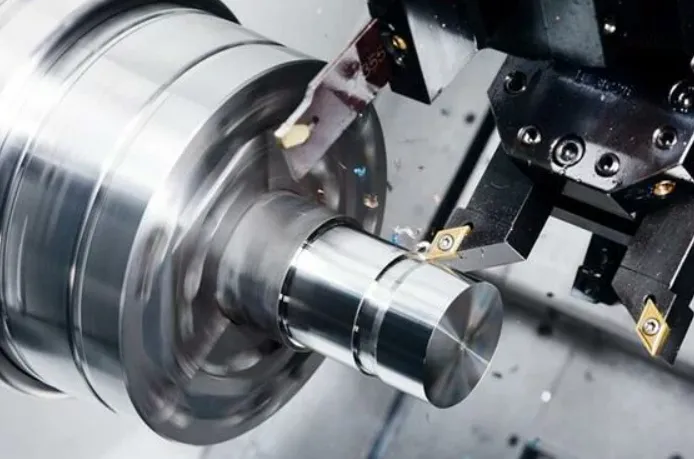

CNC precision machining has revolutionized manufacturing by delivering accuracy, repeatability, and efficiency at unprecedented levels. Modern CNC machines routinely achieve tolerances within ±0.005 mm (5 microns), with high-end systems pushing this to ±0.001 mm (1 micron) for critical aerospace and medical components. This capability is transforming industries—from automotive to electronics—where complex geometries and tight specifications are now standard requirements.

The Technology Behind Precision

At the core of CNC precision machining are advanced servo systems, high-resolution linear encoders, and rigid machine structures. Machines like the DMG MORI NHX 5500 incorporate direct-drive spindles and thermal compensation systems to maintain accuracy even during extended production runs. For example, when machining aluminum 6061-T6, these systems achieve surface finishes as fine as 0.4 µm Ra without secondary polishing—a critical factor for optical and semiconductor components.

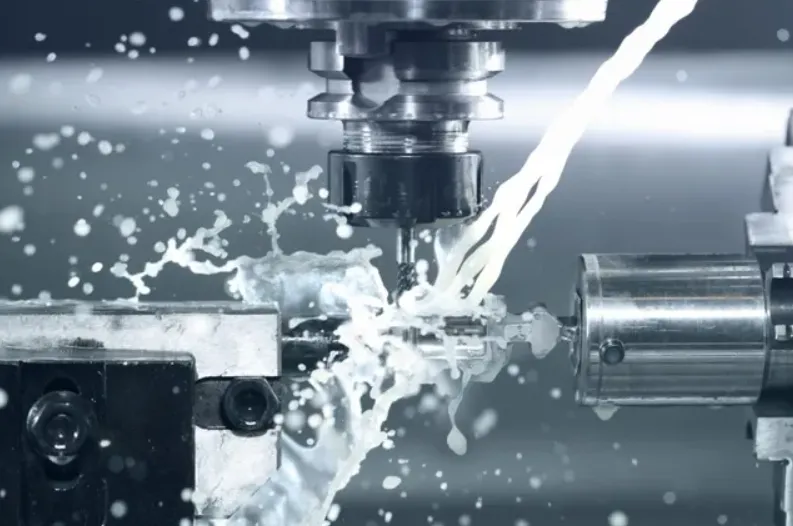

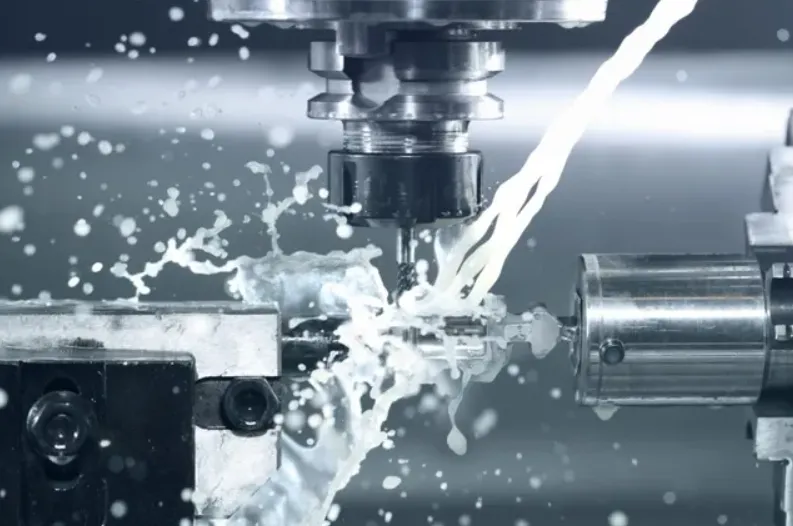

Material Advancements & Cutting Performance

The rise of high-performance alloys has demanded smarter machining strategies. Inconel 718, a nickel-based superalloy used in jet engines, requires specialized toolpaths and coolant delivery to prevent work hardening. Modern CNC machines equipped with high-pressure coolant (up to 1,000 psi) extend tool life by 300% compared to conventional flood cooling. Similarly, ceramic end mills now allow machining of hardened steels (HRC 60+) at speeds previously deemed impossible—reducing cycle times by 40% in die and mold manufacturing.

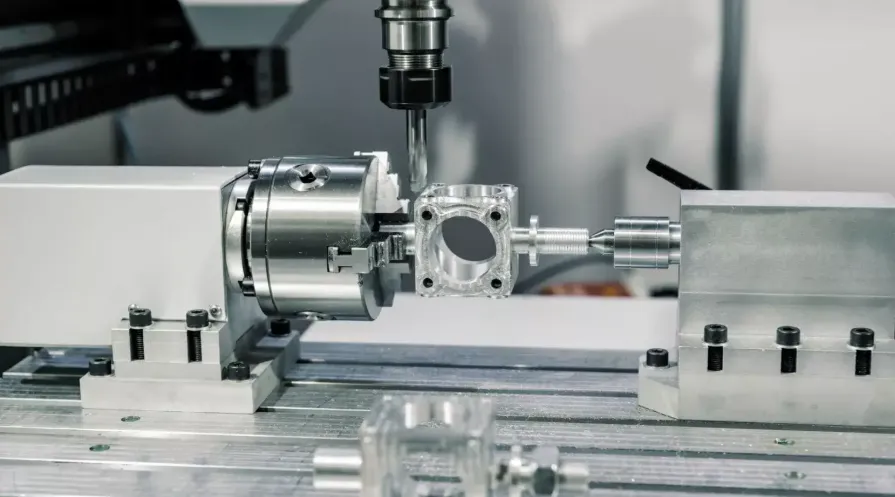

Automation & Smart Manufacturing

The integration of robotics and AI-driven process monitoring has elevated CNC machining to new efficiency levels. Automated pallet changers enable 24/7 unmanned production, while in-process probing systems measure part dimensions in real time, adjusting tool offsets to maintain tolerances within ±0.002 mm. In one automotive case study, a Mazak INTEGREX i-400S reduced scrap rates by 65% by using adaptive machining to compensate for material inconsistencies.

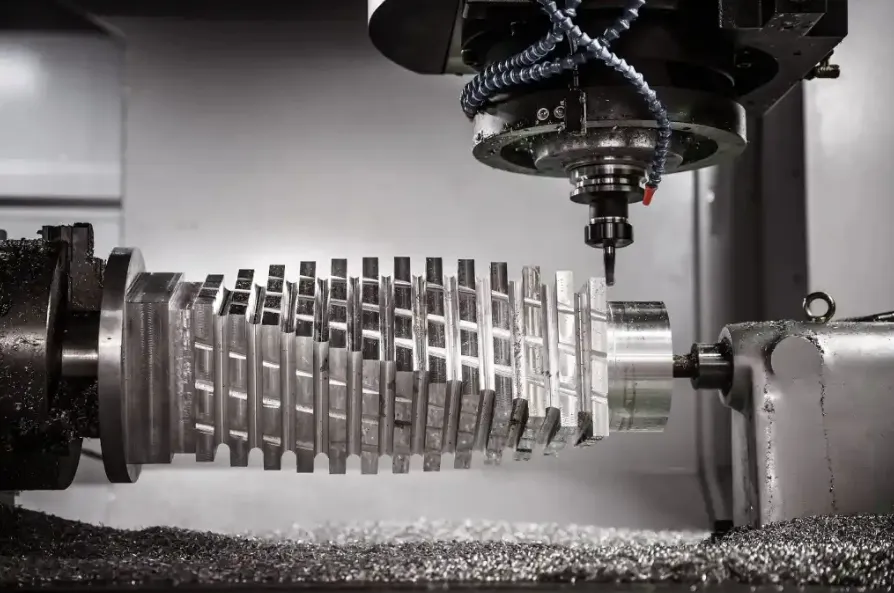

Emerging Trends: Hybrid & Micro-Machining

The future of CNC precision machining lies in hybrid manufacturing—combining additive and subtractive processes. Machines like the Okuma MU-8000V Laser EX can 3D-print metal components and then finish them to micron-level accuracy in a single setup, reducing lead times by 50% for complex aerospace parts. Meanwhile, ultra-precision micro-machining centers now produce medical stents and microfluidic devices with features as small as 20 µm, opening new possibilities in biotechnology.

Sustainability & Cost Efficiency

Beyond speed and accuracy, modern CNC machining emphasizes sustainability. Advanced CAM software optimizes toolpaths to minimize material waste, while energy-efficient spindles and servo motors reduce power consumption by 30% compared to older models. In high-volume production, these improvements translate to lower per-part costs without sacrificing quality.

Conclusion

CNC precision machining remains at the forefront of industrial innovation, driven by smarter machines, better materials, and seamless automation. As industries demand tighter tolerances and faster turnarounds, the technology continues to evolve—ensuring that manufacturers can meet tomorrow’s challenges with confidence. Whether producing turbine blades or smartphone components, CNC machining proves indispensable in an era where precision defines progress.