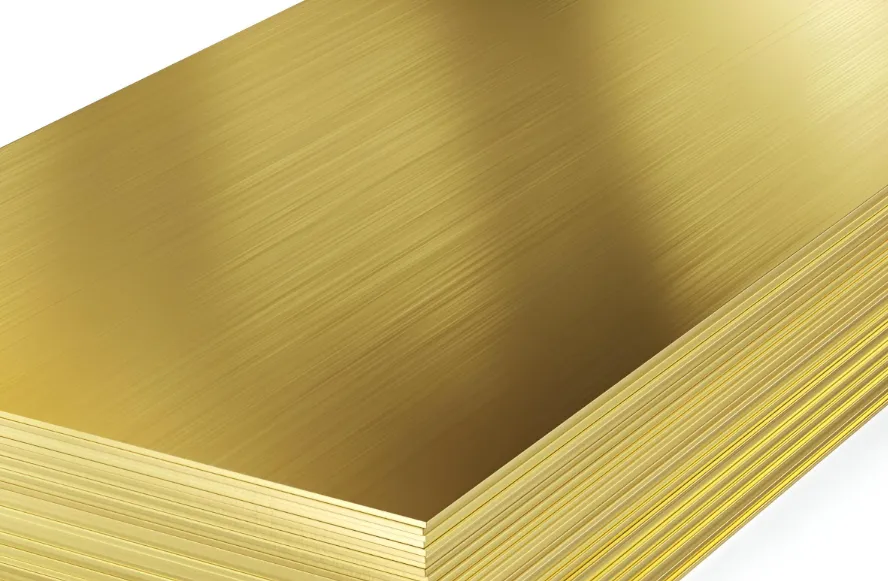

Brass sheet metal, an alloy primarily composed of copper and zinc, has been a cornerstone in various industries for centuries. Renowned for its excellent machinability, corrosion resistance, and aesthetic appeal, brass sheet metal continues to play a pivotal role in applications ranging from decorative arts to industrial machinery. This article delves into the characteristics, manufacturing processes, applications, and advantages of brass sheet metal, underscoring its enduring significance in today’s technological landscape.

Composition and Properties

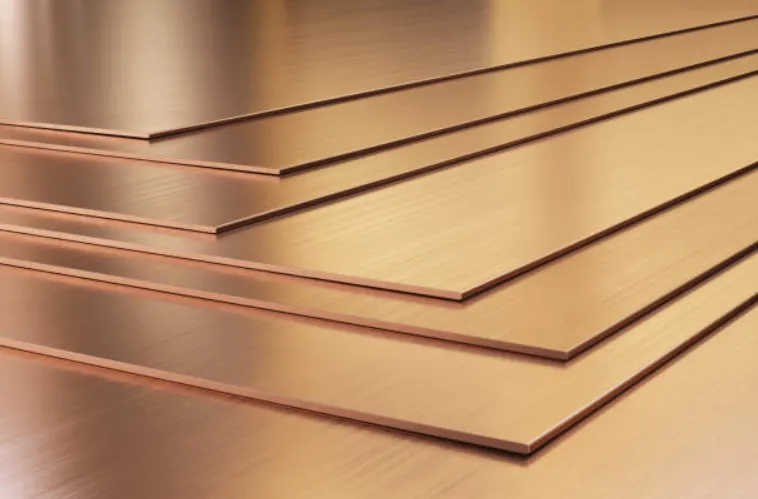

Brass is an alloy consisting mainly of copper (typically between 55-95%) and zinc (around 5-45%), with the proportion varying based on desired properties. Additional elements such as lead, manganese, and tin may be incorporated to enhance specific characteristics.

Key Properties:

- Ductility and Malleability: Brass sheet metal can be easily formed into complex shapes without cracking, making it ideal for intricate designs.

- Corrosion Resistance: The alloy exhibits significant resistance to rust and tarnishing, particularly in environments with moisture or pollutants.

- Thermal and Electrical Conductivity: Brass maintains good conductivity, although it is slightly lower than pure copper, making it suitable for electrical applications.

- Aesthetic Appeal: Its bright, gold-like appearance makes brass a preferred material for decorative elements and consumer goods.

Manufacturing Processes

The production of brass sheet metal involves several key steps to ensure consistency and quality:

- Alloying: Copper and zinc are melted together in precise proportions to create the desired brass alloy. The process may include additional elements to enhance specific properties.

- Casting: The molten brass is cast into slabs, billets, or other preliminary shapes suitable for further processing.

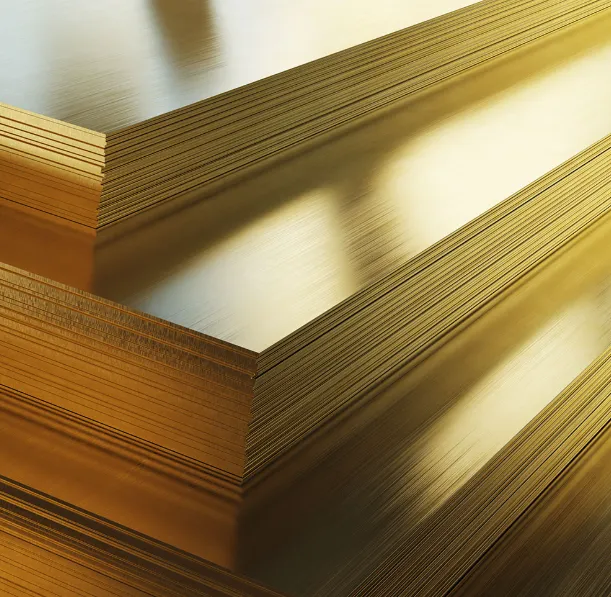

- Hot Rolling: The cast brass is heated and passed through rollers to reduce thickness and form it into sheets. This process improves the material’s grain structure, enhancing its mechanical properties.

- Annealing: To increase ductility, the rolled sheets undergo annealing—controlled heating and cooling—which relieves internal stresses and softens the metal for subsequent forming.

- Finishing: The brass sheets may be further processed through cold rolling, surface treatments, or coatings to achieve the desired finish and surface characteristics.

Applications of Brass Sheet Metal

Brass sheet metal’s versatility makes it indispensable across various sectors:

- Automotive Industry: Used in manufacturing decorative trims, radiator cores, and components requiring good thermal conductivity and corrosion resistance.

- Electrical and Electronics: Utilized in connectors, switches, and circuit boards due to its reliable electrical properties.

- Plumbing: Employed in fittings, valves, and fixtures that benefit from brass’s resistance to corrosion and biofouling.

- Consumer Goods: Incorporated in musical instruments, jewelry, hardware, and architectural elements for its aesthetic appeal and workability.

- Marine Applications: Preferred for marine hardware and components exposed to seawater, leveraging its excellent corrosion resistance.

Advantages of Brass Sheet Metal

- Workability: Brass can be easily cut, bent, and formed into complex shapes without compromising structural integrity, reducing manufacturing time and costs.

- Longevity: Its resistance to corrosion and wear ensures durable products with long service lives, minimizing maintenance requirements.

- Recyclability: Brass is fully recyclable without loss of properties, promoting sustainable practices and reducing environmental impact.

- Aesthetic Versatility: Available in various finishes, including polished, brushed, or antiqued, brass sheet metal can be tailored to match diverse design aesthetics.

- Antimicrobial Properties: Naturally inhibiting the growth of bacteria and other microorganisms, brass is increasingly used in healthcare settings for surfaces and fixtures.

Market Trends and Future Outlook

As of 2023, the global brass market has been experiencing steady growth, driven by demand from the automotive, construction, and electronics sectors. Innovations in alloy formulations and manufacturing techniques continue to expand brass sheet metal’s applicability. Additionally, the push towards sustainable materials in manufacturing underscores brass’s recyclability and longevity as key advantages.

Emerging technologies, such as additive manufacturing (3D printing) with brass alloys, are opening new avenues for customization and rapid prototyping, further cementing brass sheet metal’s role in modern industry.

Conclusion

Brass sheet metal stands out as a highly adaptable and reliable material, balancing functional performance with aesthetic qualities. Its enduring presence across diverse applications underscores its significance in both traditional and cutting-edge industries. As technology advances and sustainability becomes increasingly paramount, brass sheet metal is poised to maintain its vital role, continuing to meet the evolving needs of manufacturers and consumers alike.