Plastic CNC (Computer Numerical Control) machining is an advanced manufacturing process that has gained significant traction in various industries due to its efficiency and precision in producing plastic components. As the demand for custom plastic parts continues to rise, understanding the principles and advantages of plastic CNC machining becomes increasingly important for engineers and manufacturers. This article will delve into the intricacies of plastic CNC machining, its applications, benefits, and considerations for successful implementation.

Understanding Plastic CNC Machining

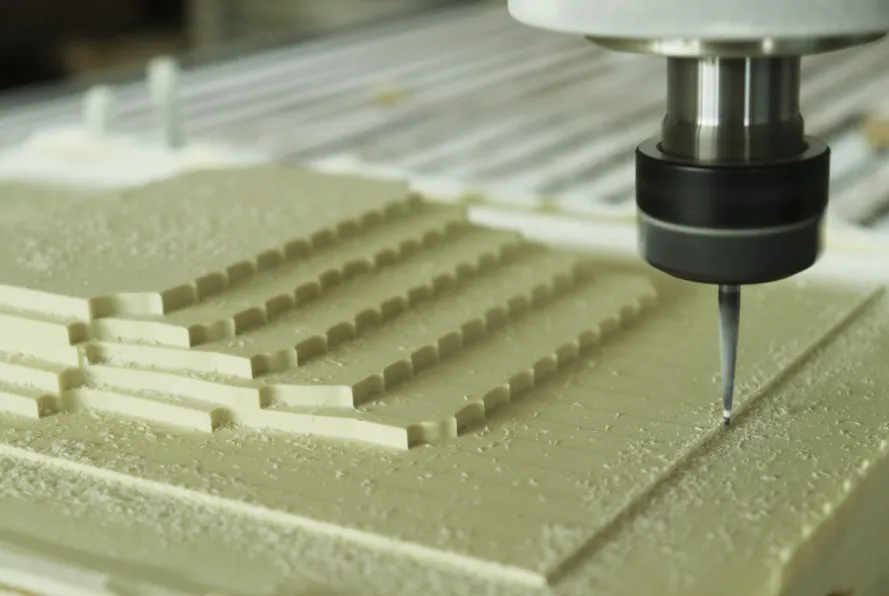

CNC machining refers to the process of using computer-controlled machinery to create parts from a digital file. In the case of plastic CNC machining, various types of plastics are machined into specific components based on detailed specifications. The process involves the removal of material from a solid plastic block using a variety of cutting tools, enabling the production of complex shapes that would be difficult to achieve with traditional manufacturing methods.

Common Types of Plastics Used in CNC Machining

Several types of plastic materials are suitable for CNC machining, each with unique properties that make them ideal for specific applications:

-

Acrylic (PMMA): Known for its clarity and impact resistance, acrylic is often used in applications where transparency is desired, such as display cases and lighting covers.

-

Polycarbonate (PC): With exceptional strength and heat resistance, polycarbonate is commonly used in applications such as safety goggles and automotive components.

-

Polyamide (Nylon): Nylon is known for its excellent wear resistance and low friction properties, making it ideal for gears, bearings, and other mechanical components.

-

Polyoxymethylene (POM): Also known as acetal, POM is used for precision parts that require high stiffness and dimensional stability, making it suitable for automotive and aerospace applications.

-

Polyethylene (PE): This thermoplastic is used in various applications due to its chemical resistance and durability, often found in packaging and container production.

The CNC Machining Process for Plastics

The CNC machining process for plastics involves several key steps:

-

Design and CAD Modeling: The process begins with the creation of a 3D model using Computer-Aided Design (CAD) software. This model includes all necessary specifications, dimensions, and tolerances for the finished component.

-

CAM Programming: The CAD model is then converted into a format that CNC machines can understand, typically G-code, through Computer-Aided Manufacturing (CAM) software. This programming defines the machining paths and parameters.

-

Machine Setup: The CNC machine is set up with the appropriate tooling and the plastic material is secured on the machine bed. Proper alignment and calibration are essential for achieving desired precision.

-

Machining Process: The CNC machine executes the programmed instructions, using various cutting tools to shape the plastic material. This can include milling, drilling, turning, and routing operations.

-

Quality Control and Finishing: Once machining is complete, the parts undergo inspection to ensure they meet quality standards. This may involve measurement techniques such as Coordinate Measuring Machines (CMM). After passing inspection, additional finishing processes like sanding, polishing, or coating may be applied.

Advantages of Plastic CNC Machining

Plastic CNC machining offers numerous benefits that enhance its applicability in various industries:

-

High Precision and Accuracy: CNC machining delivers exceptional precision, with tolerances typically within ±0.005 inches. This makes it ideal for applications requiring meticulous specifications.

-

Complex geometries: The versatility of CNC machines allows for the production of intricate and complex shapes that would be challenging to achieve with traditional machining or molding processes.

-

Cost-Effectiveness for Prototyping: CNC machining is an excellent choice for creating prototypes and small production runs, as it allows for rapid adjustments and modifications without the high costs associated with large-scale production.

-

Material Optimization: The subtractive nature of CNC machining helps to minimize waste by using only the necessary amount of material for fabrication. This is particularly advantageous when working with expensive engineering plastics.

-

Short Lead Times: Due to the efficiency of CNC machining, parts can be produced quickly, helping companies reduce lead times and respond swiftly to market demands.

Applications of Plastic CNC Machining

Plastic CNC machining finds applications across various industries, including:

-

Aerospace: Components such as air ducts, housings, and interior fittings are machined from lightweight plastics to reduce overall aircraft weight and improve fuel efficiency.

-

Automotive: Custom plastic parts like dashboards, trim pieces, and under-the-hood components are produced to meet specific functional and aesthetic requirements.

-

Medical Devices: Precision machined plastic parts are used in medical equipment, including housings for devices, surgical instruments, and prototypes for testing.

-

Consumer Products: Many everyday items, from kitchen utensils to electronic housings, are manufactured using CNC machining to achieve desired aesthetics and functionality.

-

Electronics: The electronics industry utilizes plastic CNC machining for components like enclosures, connectors, and circuit board supports, ensuring reliability and performance.

Considerations for Successful Plastic CNC Machining

While plastic CNC machining offers numerous advantages, there are essential factors to consider for successful implementation:

-

Material Selection: Choosing the right plastic material is critical, as each type has distinct properties that influence machining performance and suitability for specific applications.

-

Tooling and Machining Parameters: Appropriate tooling and machining parameters, such as feed rate, spindle speed, and tool geometry, must be optimized for the specific plastic being machined to achieve the best results.

-

Thermal Management: Plastic materials can generate heat during machining, affecting dimensional stability. Implementing proper cooling methods, such as misting or airflow, can help mitigate these effects.

-

Post-Machining Treatments: Depending on the application, post-machining treatments may be necessary to enhance surface finish, increase durability, or improve aesthetic qualities.

Conclusion

Plastic CNC machining is a powerful manufacturing process that enables the production of high-precision plastic components across various industries. Its capability to create complex geometries, coupled with advantages such as reduced lead times, cost-effectiveness, and material optimization, makes it a preferred choice for manufacturers. As technology continues to advance, the potential applications and innovations in plastic CNC machining are bound to expand, contributing to the evolution of modern manufacturing solutions. Understanding the principles and best practices of this technology is vital for engineers and professionals seeking to leverage the benefits of plastic CNC machining in their projects.