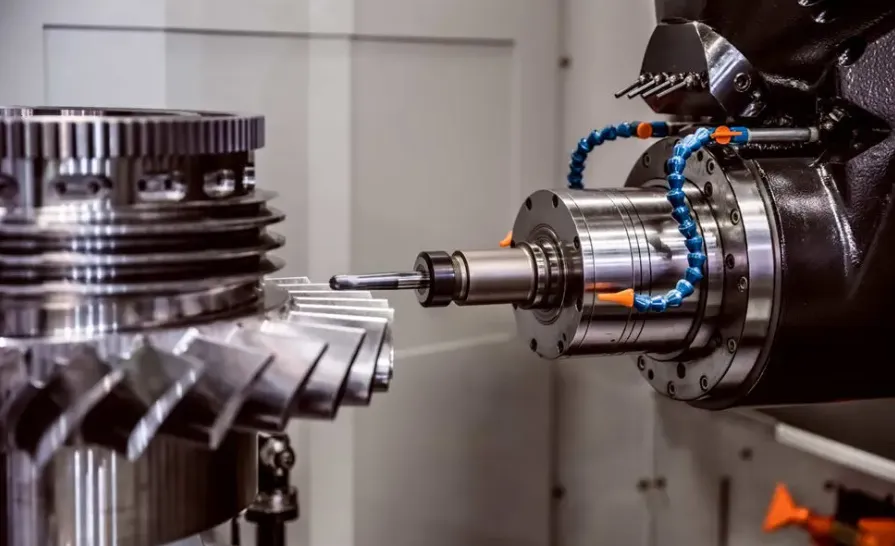

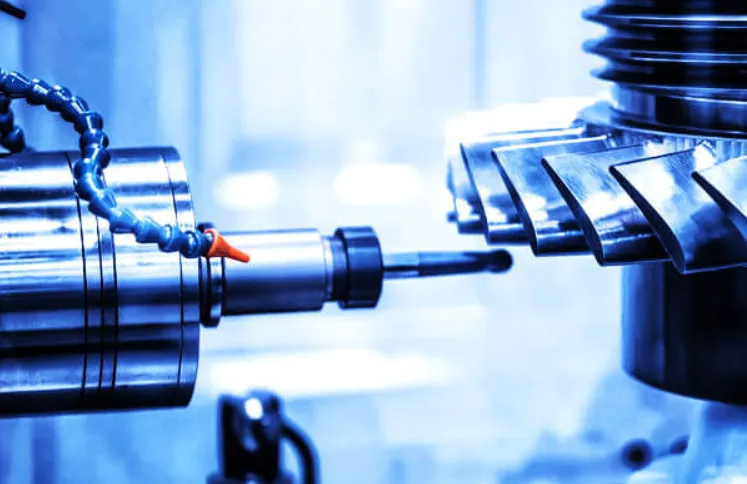

Precision CNC (Computer Numerical Control) machining has emerged as a vital technology in modern manufacturing, enabling the production of complex parts and components with high accuracy and minimal waste. This advanced machining process has transformed various industries, including aerospace, automotive, medical devices, and electronics. In this article, we will explore the principles of precision CNC machining, its advantages, applications, and the future of this indispensable technology.

Understanding CNC Machining

CNC machining refers to the process of using computer-controlled machines to operate tools such as mills, lathes, routers, and grinders. The “precision” in precision CNC machining emphasizes the high level of accuracy and repeatability achieved through this technology. Unlike traditional machining methods, which rely heavily on manual labor and skills, CNC machines operate based on precise computer-generated instructions.

How Precision CNC Machining Works

The CNC machining process involves several key steps:

-

Design and CAD Modeling: The first step is creating a detailed design of the part or component using CAD (Computer-Aided Design) software. Engineers and designers build a 3D model that includes all necessary specifications, dimensions, and tolerances.

-

CAM Programming: Once the design is complete, the CAD file is converted into a language that the CNC machine can understand, usually G-code. This step is done through CAM (Computer-Aided Manufacturing) software, which generates the machining instructions based on the designed model.

-

Machine Setup: The CNC machine is then set up with the appropriate tools, and the material (such as metal, plastic, or composite) is loaded onto the machine bed. Precision is critical at this stage, as even minor discrepancies can affect the final product.

-

Machining Process: The CNC machine follows the programmed instructions to cut, shape, and finish the material. Sensors and feedback systems continuously monitor the machining process to ensure accuracy.

-

Quality Control and Inspection: After the machining is complete, the finished parts are subjected to rigorous quality control measures. This may involve the use of Coordinate Measuring Machines (CMM) and other inspection tools to verify dimensions and tolerances.

Advantages of Precision CNC Machining

Precision CNC machining offers numerous benefits that contribute to its growing popularity in the manufacturing sector:

1. High Accuracy and Consistency

One of the primary advantages of precision CNC machining is its ability to produce parts with extremely high accuracy and repeatability. CNC machines can achieve tolerances within ±0.001 inches or better, making them suitable for industries where precision is critical.

2. Complex Geometries

CNC machining allows for the creation of intricate designs and complex geometries that may be difficult or impossible to achieve with traditional machining methods. This capability is especially valuable in industries like aerospace and medical devices, where components often have unique shapes.

3. Reduced Lead Times

The automation of the machining process significantly reduces lead times. Once the CAD model and CAM program are established, producing identical parts becomes much faster, allowing manufacturers to respond quickly to market demands.

4. Minimized Waste

Precision CNC machining optimizes material usage by planning the machining path to minimize waste. This is particularly important for expensive materials, as it helps reduce costs and environmental impact.

5. Flexibility and Adaptability

CNC machines can easily be reprogrammed to produce different parts, making them versatile for various manufacturing tasks. This adaptability reduces downtime and allows manufacturers to switch between projects without significant delays.

Applications of Precision CNC Machining

Precision CNC machining is used across a wide range of industries due to its versatility and capability. Some of the notable applications include:

1. Aerospace

In the aerospace industry, precision is non-negotiable. Components such as turbine blades, structural elements, and fittings require meticulous machining to meet strict regulations and safety standards. CNC machining helps aerospace manufacturers achieve the necessary quality and precision while reducing lead times.

2. Automotive

The automotive industry employs CNC machining for manufacturing various parts, including engine components, transmission cases, and interior fittings. The ability to produce complex shapes and high volumes quickly makes CNC machining ideal for automotive applications.

3. Medical Devices

Precision CNC machining plays a critical role in the production of medical devices and instruments. Components such as surgical tools, implants, and diagnostic equipment must meet stringent regulatory requirements, and CNC machining ensures the required accuracy and biocompatibility.

4. Electronics

The electronics industry relies on precision CNC machining for the creation of enclosures, housings, and circuit boards. The ability to manufacture small, intricate parts with tight tolerances is essential for producing reliable electronic devices.

5. Industrial Equipment

Various mechanical and industrial equipment components are produced using CNC machining. This includes gears, valves, and custom machine parts that require high precision for optimal performance.

The Future of Precision CNC Machining

The future of precision CNC machining looks promising, with several emerging trends and technologies that will likely shape its evolution:

1. Integration of AI and Machine Learning

Artificial intelligence (AI) and machine learning algorithms are increasingly being integrated into CNC machining processes. These technologies can optimize machining parameters, predict maintenance needs, and enhance automation, leading to improved efficiency and reduced costs.

2. Additive Manufacturing Collaboration

The combination of CNC machining and additive manufacturing (3D printing) is expected to grow. This hybrid approach allows manufacturers to leverage the strengths of both technologies, producing complex parts with reduced material waste and enhanced performance.

3. Smart Manufacturing and IoT

The adoption of smart manufacturing concepts and the Internet of Things (IoT) in CNC machining will enable manufacturers to monitor and control machines remotely. Data analytics will play a crucial role in improving production efficiency and predictive maintenance strategies.

4. Sustainable Practices

As the manufacturing industry shifts towards sustainability, precision CNC machining will evolve to include greener practices. This may involve using eco-friendly materials, reducing energy consumption, and minimizing waste throughout the machining process.

Conclusion

Precision CNC machining is a cornerstone of modern manufacturing, providing unparalleled accuracy and versatility across various industries. Its ability to produce complex parts and reduce waste while maintaining high-quality standards makes it an essential technology for today’s competitive market. As advancements in AI, additive manufacturing, and smart technologies continue to emerge, the future of precision CNC machining promises to be even more innovative and efficient, paving the way for a new era in manufacturing.