Corrosion poses a significant threat to the integrity and longevity of materials used in various industrial applications. To combat this issue, corrosion-resistant alloys (CRAs) have been developed, combining different metals to enhance durability and resistance to corrosive environments. This article explores the composition, benefits, applications, and future developments of corrosion-resistant alloys.

What are Corrosion-Resistant Alloys?

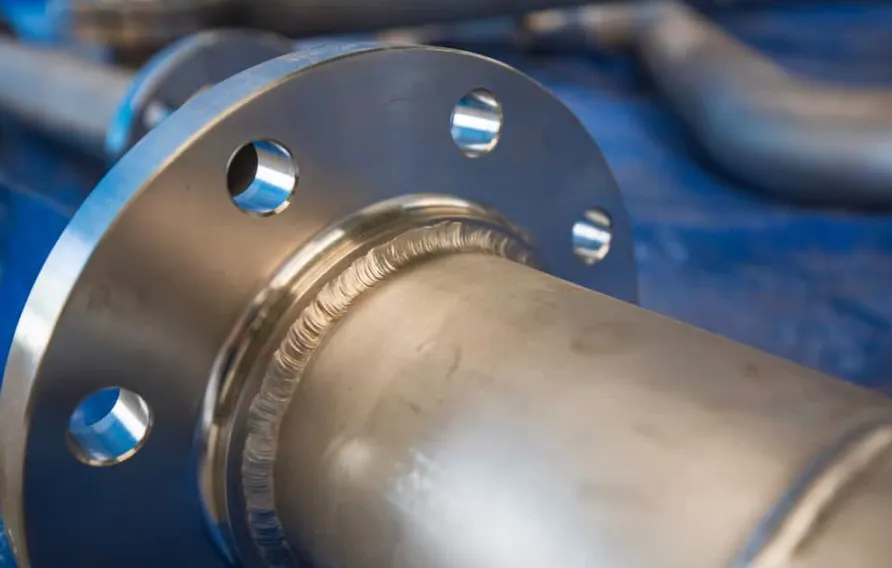

Corrosion-resistant alloys are specially engineered materials designed to withstand degradation due to chemical or electrochemical reactions. These reactions can be triggered by environmental factors such as moisture, acids, and other corrosive agents. CRAs are characterized by their unique alloying elements, which provide enhanced resilience compared to traditional metals and alloys.

- Common Types of Corrosion-Resistant Alloys:

- Stainless Steel: This widely used alloy contains a minimum of 10.5% chromium, which serves to form a protective oxide layer that prevents rust.

- Nickel Alloys: Alloys such as Inconel and Hastelloy offer excellent corrosion resistance in extreme environments, making them ideal for the aerospace and chemical industries.

- Titanium Alloys: Known for their exceptional strength-to-weight ratio and resistance to corrosion, titanium alloys are particularly effective in marine applications.

Advantages of Using Corrosion-Resistant Alloys

The use of corrosion-resistant alloys brings several notable advantages:

-

Extended Lifespan: CRAs significantly reduce wear and tear, extending the operational life of components and structures in corrosive environments.

-

Reduced Maintenance Costs: By minimizing the need for repairs and replacements, CRAs help lower overall maintenance costs for equipment and infrastructure.

-

Enhanced Safety: Since CRAs resist degradation better than conventional materials, they help maintain safety standards, particularly in sectors like oil and gas, where failures can lead to catastrophic incidents.

Applications of Corrosion-Resistant Alloys

Corrosion-resistant alloys are utilized in various industries due to their unique properties:

-

Oil and Gas: In offshore drilling operations and refineries, CRAs are essential for piping, valves, and other equipment exposed to corrosive substances like seawater and hydrogen sulfide.

-

Aerospace: Components made from CRAs can endure harsh environments and extreme temperatures, making them suitable for aircraft engines and structural elements.

-

Chemical Processing: Equipment used in the production and transportation of chemicals often incorporates CRAs to withstand aggressive environments.

Innovations and Future Trends

Research and development in corrosion-resistant alloys continue to evolve, highlighting a few key trends:

-

Advanced Alloys: Ongoing innovations focus on developing new alloys that provide greater resistance to specific types of corrosion, such as pitting and crevice corrosion.

-

Nanotechnology: The incorporation of nanomaterials can enhance the protective properties of existing alloys, leading to improved performance.

-

Sustainability: Manufacturers are increasingly considering the environmental impact of alloy production, leading to efforts to create sustainable CRAs while reducing harmful emissions during fabrication.

Conclusion

Corrosion-resistant alloys play a crucial role in protecting materials from the detrimental effects of corrosion in various applications. Their ability to withstand harsh environments not only enhances the longevity of products but also contributes to safety, efficiency, and cost-effectiveness in multiple industries. As technology advances, the development of new and improved corrosion-resistant alloys will continue to impact how we approach materials science and engineering, ensuring robust solutions for the challenges of the future.