In today’s manufacturing landscape, the quest for precision and efficiency is more critical than ever. A key player in achieving these goals is the 5-axis workholding system. This article explores the fundamental aspects of 5-axis workholding and its transformative role in modern machining processes.

What is 5-Axis Workholding?

5-axis workholding refers to the equipment and systems designed to securely hold a workpiece on CNC (computer numerical control) machines that operate across five axes simultaneously. This capability distinguishes 5-axis machining from traditional 3-axis methods, allowing for the creation of intricate parts with complex geometries. As manufacturers strive to achieve greater accuracy, the need for effective workholding solutions has never been higher.

Key Components of 5-Axis Workholding

-

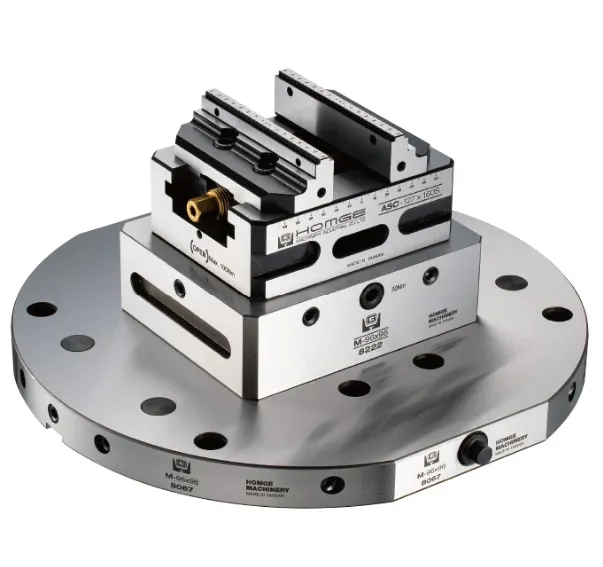

Vises: Specialized vises tailored for 5-axis applications enable manufacturers to clamp workpieces with minimal obstructions, providing better access for machining tools.

-

Fixtures: Custom fixtures can be designed to accommodate various shapes and sizes, ensuring that different workpieces are held securely during machining.

-

Pallet Systems: These systems streamline workflows by allowing rapid exchanges between multiple workpieces, significantly reducing setup times.

Advantages of 5-Axis Workholding

The adoption of 5-axis workholding systems offers several notable advantages:

-

Enhanced Precision: By allowing tools to approach the workpiece from multiple angles, manufacturers can achieve tighter tolerances and greater accuracy in finished products.

-

Time Efficiency: Quick-change mechanisms in 5-axis systems reduce setup times, enabling faster transitions between jobs and improved overall productivity.

-

Superior Surface Finish: The capability to access complex geometries reduces toolpath lengths, leading to smoother surface finishes and minimizing the need for additional finishing processes.

Innovations Shaping 5-Axis Workholding

The field of 5-axis workholding has seen significant technological advancements in recent years:

-

Automation: Many systems now incorporate automation and IoT technology, allowing for real-time adjustments to clamping and positioning, further enhancing process efficiency.

-

Advanced Materials: Developments in lightweight yet durable materials result in more resilient workholding solutions that can withstand higher pressures without deforming.

-

Sophisticated Software: Integration with advanced CAM (computer-aided manufacturing) software provides operators with tools to plan and simulate machining operations effectively, ensuring optimal workholding configurations.

Conclusion

As the manufacturing industry continues to evolve, the significance of 5-axis workholding systems cannot be overstated. These solutions not only enhance precision and productivity but also empower manufacturers to tackle complex machining challenges head-on. By leveraging advancements in 5-axis workholding, companies can remain competitive in a fast-paced market, continually pushing the boundaries of what is achievable in precision manufacturing. The future of this technology promises even more exciting developments, set to transform the machining landscape further.●