In recent years, CNC (Computer Numerical Control) automation has revolutionized the manufacturing landscape, ushering in a new era of efficiency, precision, and flexibility. This technological advancement offers companies the ability to produce intricate parts with minimal human intervention, thus optimizing production processes and reducing errors.

Understanding CNC Automation

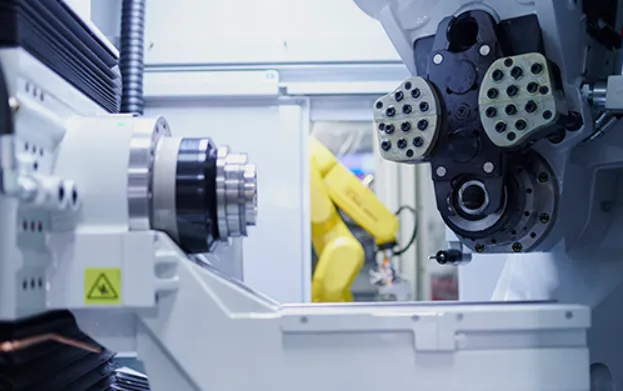

CNC automation integrates computer technology with manufacturing processes to optimize and control machinery and tools. By converting manual operations into automated sequences, manufacturers can achieve higher productivity levels while maintaining superior accuracy. This system uses programmed commands to guide tools, allowing for complex manufacturing tasks to be executed repetitively without the variability associated with manual labor.

The essence of CNC automation lies in its ability to manage various tools and functions through software, enabling machines to perform tasks such as drilling, milling, turning, and grinding with remarkable precision. With CNC technology, intricate designs can be achieved, substantially reducing production time and waste.

Advantages of CNC Automation

-

Enhanced Efficiency: One of the most compelling benefits of CNC automation is the marked increase in production efficiency. CNC machines can operate continuously, processing multiple parts with programmed precision. According to a 2023 study, automated CNC systems can accelerate production speeds up to 40% compared to traditional methods, significantly improving turnaround times for manufacturers.

-

Precision and Quality Control: The precision of CNC automation allows for the production of parts with tolerances as tight as ±0.001 inches (±0.0254 mm). This level of accuracy is critical in industries such as aerospace and medical device manufacturing, where even minor deviations can lead to substantial failures. Automated systems also minimize human error, leading to a consistent quality of output.

-

Flexibility in Production: CNC automation provides manufacturers with the flexibility to shift production lines quickly. With the capability of switching between different tasks through software adjustments, companies can easily adapt to changing market demands without significant downtime. This adaptability is particularly valuable in today’s fast-paced economic environment.

-

Cost-Effectiveness: Although the initial investment in CNC automation systems can be considerable, the long-term cost savings are substantial. Reduced labor costs, minimized waste, and enhanced production efficiencies lead to significant savings over time. Many manufacturers report that CNC automation can yield a return on investment within two to three years, depending on operation scale.

-

Safety Improvements: Automation enhances workplace safety by reducing the need for manual interventions in potentially hazardous environments. CNC systems can be programmed to perform dangerous tasks, thereby keeping human operators at a safe distance from harmful machinery and harmful materials.

Trends Shaping the Future of CNC Automation

As we move further into the 21st century, several key trends are emerging in the realm of CNC automation:

-

Integration of Artificial Intelligence: AI technologies are increasingly being integrated into CNC systems, enabling smarter decision-making and predictive maintenance. AI algorithms can analyze machine performance data in real-time, assisting operators in identifying potential issues before they lead to downtime.

-

Internet of Things (IoT) Connectivity: The integration of IoT technology within CNC machining allows for greater connectivity and monitoring capabilities. Manufacturers are now able to gather and analyze data from various machines on the shop floor, facilitating enhanced productivity tracking, remote monitoring, and real-time adjustments.

-

Sustainability in Manufacturing: Eco-friendly practices are becoming paramount in modern manufacturing. CNC automation allows for more efficient use of materials, resulting in less waste. Furthermore, energy-efficient CNC machines reduce consumption and environmental impact, aligning with global sustainability goals.

-

Collaborative Robotics (Cobots): The rise of collaborative robots is making waves in CNC automation. These robots work alongside human operators to assist in various tasks, enhancing productivity without replacing the human workforce. They are particularly beneficial in environments that require a mix of automated and manual operations.

Conclusion

CNC automation is not just a trend; it is a cornerstone of modern manufacturing that is reshaping industries across the globe. The advantages of enhanced efficiency, precision, flexibility, cost-effectiveness, and improved safety make it an essential investment for manufacturers looking to maintain competitive advantages in an increasingly demanding marketplace. As technologies continue to integrate and evolve, the future of CNC automation promises even greater innovations that will drive productivity and redefine the standards of manufacturing excellence. The ongoing journey of CNC automation is one that not only paves the way for manufacturing advancement but also sets a benchmark for operational efficiency in the years to come.