Trepanning machining is a specialized process used to create large-diameter holes with high precision and efficiency. It involves the use of a cutting tool that removes material in a circular pattern, effectively generating a cylindrical void without the need to drill out the entire mass of material. This method has gained prominence in various industries, such as aerospace, automotive, and manufacturing, particularly as manufacturers seek to balance productivity and quality in their machining processes.

The Trepanning Process

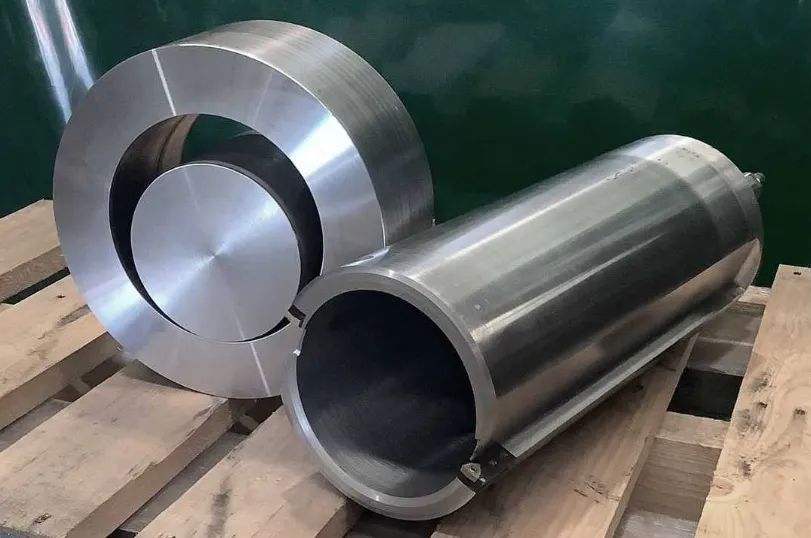

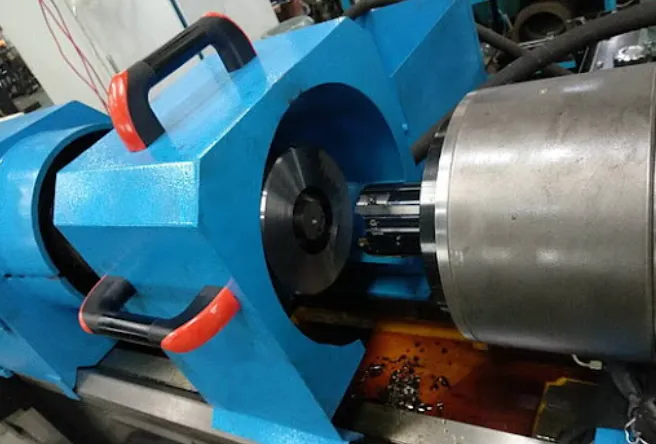

Trepanning is distinct from conventional drilling techniques in that instead of removing all the material from an enclosed area to create a hole, it cuts a ring around the perimeter. The cutting tool, often referred to as a trepanning tool, is typically a single-point tool used to excavate the inner material, leaving a cylindrical core. The primary advantages of this method include reduced material waste, lower cutting forces, and the ability to handle larger diameter holes without compromising structural integrity.

The trepanning operation can be performed on various materials, including metals, plastics, and composites. Tools used in this technique often come equipped with high-speed steel or carbide inserts designed for durability and extended service life. The process can be optimized for different materials and geometries, ensuring flexibility and adaptability in production.

Advantages of Trepanning Machining

-

Efficiency: Trepanning is known for its ability to quickly remove large volumes of material compared to traditional drilling methods. This efficiency can lead to significant time savings in production, particularly for high-volume applications.

-

Reduced Tool Wear: Because the cutting tool is designed to remove material only along the perimeter, it experiences less wear compared to conventional drilling. This results in longer tool life and fewer tool changes, minimizing downtime.

-

High Precision: The process produces holes with smooth surfaces and precise dimensions, essential in applications where tight tolerances are required. The trepanning operation can achieve diameters that might be challenging to drill conventionally.

-

Less Material Waste: Unlike traditional methods that create chips from the entirety of the drilled area, trepanning conservatively removes only the necessary material. This characteristic is advantageous in industries focused on sustainability and cost efficiency.

-

Variety of Applications: Trepanning is especially useful for creating features in complex components, such as those found in aerospace structures, where large, lightweight structures are essential.

Applications of Trepanning Machining

Trepanning machining finds various applications across different sectors:

-

Aerospace Industry: The aerospace sector frequently leverages trepanning to produce large and intricate components such as engine casings and various structural parts. The method allows for effective weight reduction while maintaining the structural integrity of components exposed to high-stress environments.

-

Automotive Manufacturing: As the automotive industry pursues lightweight solutions that enhance fuel efficiency, trepanning is employed to create large holes in components like brake disks and flywheels.

-

Oil and Gas Sector: In the exploration and production of oil and gas, trepanning is used to drill large holes in hard materials, facilitating access to reserves without compromising the surrounding geological structure.

-

Medical Devices: Trepanning is increasingly utilized in manufacturing specialized medical equipment and devices, such as implants and surgical instruments, where precision and cleanliness are paramount.

Technological Advancements

In recent years, advancements in technology have further enhanced the capabilities and applications of trepanning machining. The integration of computer numerical control (CNC) systems enables precise programming and automation of trepanning processes, resulting in improved accuracy and consistency.

Additionally, research into electrochemical trepanning processes is showing promise in expanding the capabilities of traditional mechanical techniques. The electrochemical method can facilitate the machining of materials that are difficult to cut with conventional tools, such as titanium alloys, which are prized for their strength-to-weight ratio.

Challenges and Future Directions

Despite its benefits, trepanning machining faces specific challenges, including tool wear and the need for precise setup to achieve optimal results. As material science continues to advance, the development of new cutting materials and coatings can enhance tool life and performance, addressing issues of wear and heat generation during machining.

Future research is also likely to focus on the integration of additive manufacturing and trepanning, exploring hybrid techniques that can optimize production efficiency and design complexity.

Conclusion

Trepanning machining stands out as a critical process in modern manufacturing, providing effective solutions for creating large, precise holes across a variety of industries. As technology advances and new materials emerge, trepanning techniques will likely evolve, enhancing their applicability and efficiency. With ongoing research and innovation, the future of trepanning machining appears bright, promising continued contributions to manufacturing excellence in the years to come.