Global manufacturing is witnessing a steady push for higher precision and efficiency, driving a transformative evolution in sheet metal production. According to a Grand View Research report, the global sheet metal manufacturing market was valued at approximately USD 2300 billion in 2019, with an expected annual growth rate of around 3.7% in the coming years. Modern sheet metal production employs a series of processes including laser cutting, CNC bending, stamping, and welding assembly to guarantee precision from raw material to finished product.

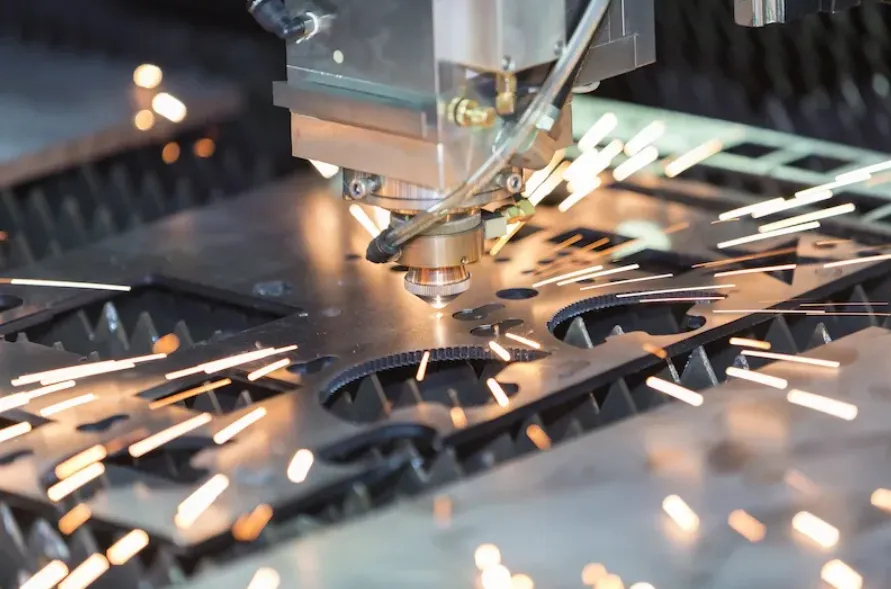

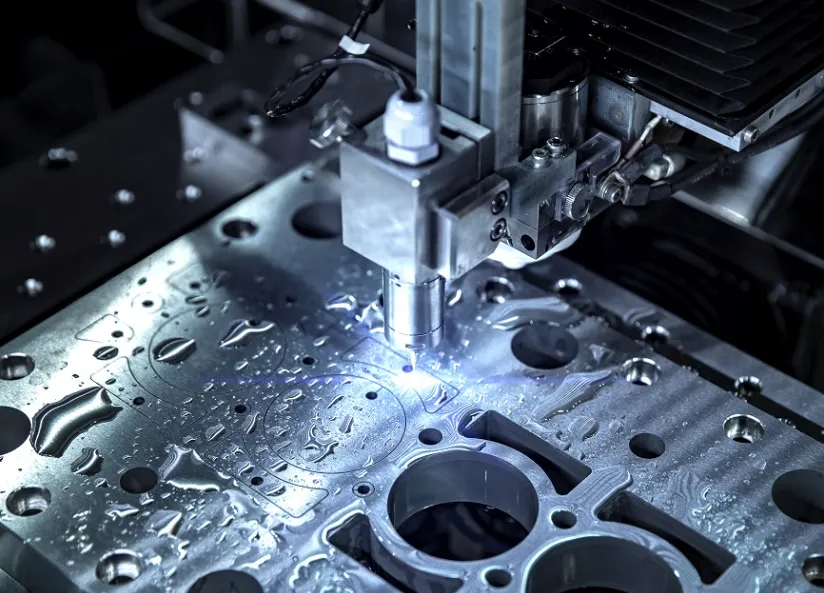

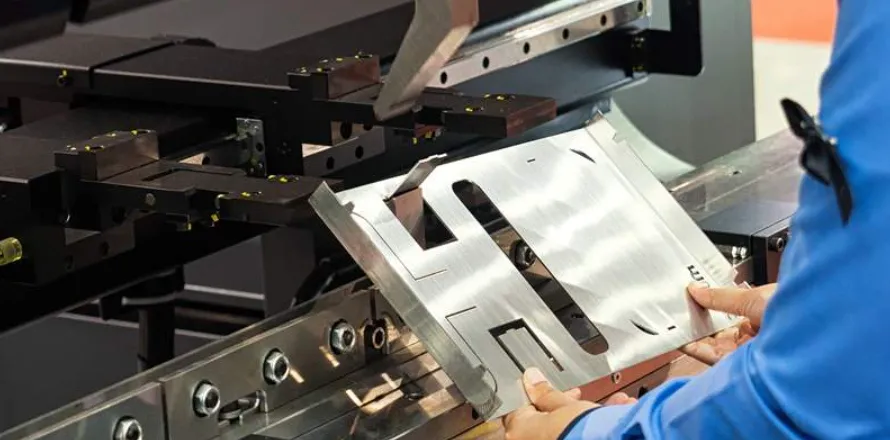

During the initial cutting phase, advanced laser and waterjet systems are commonly used to slice large metal sheets into prescribed shapes. Current laser cutting systems can achieve dimensional tolerances as tight as ±0.02 millimeters, laying a robust foundation for subsequent processes. In the bending stage, CNC-powered equipment utilizes high-accuracy servo systems and precision sensors to ensure bending errors remain within ±0.01 millimeters, which is critical for meeting stringent global industry standards.

During the initial cutting phase, advanced laser and waterjet systems are commonly used to slice large metal sheets into prescribed shapes. Current laser cutting systems can achieve dimensional tolerances as tight as ±0.02 millimeters, laying a robust foundation for subsequent processes. In the bending stage, CNC-powered equipment utilizes high-accuracy servo systems and precision sensors to ensure bending errors remain within ±0.01 millimeters, which is critical for meeting stringent global industry standards.

The stamping process leverages high-frequency punch presses and custom-designed dies to form metal parts efficiently. State-of-the-art stamping machines are capable of delivering thousands of strokes per minute, providing remarkable benefits in production throughput and consistency. In the realm of welding and assembly, robotic welding systems have been widely adopted, with some advanced production lines reporting product acceptance rates exceeding 98%. Automated systems not only improve quality by mitigating human error but also reduce the time required for production cycles.

Material selection is integral to sheet metal manufacturing, with aluminum alloys, low-carbon steel, and stainless steel being the most commonly used. Aluminum alloys, with a typical density of about 2.7 grams per cubic centimeter, are especially prized in aerospace and automotive sectors for their lightweight yet strong properties, while stainless steel is favored in construction and chemical processing for its excellent corrosion resistance. Some companies are also pioneering the use of composite materials that incorporate multi-layer sandwich structures to achieve both high strength and weight reduction.

Environmental considerations are increasingly essential in today’s sheet metal manufacturing. Leading enterprises have achieved metal scrap recycling rates exceeding 90%, which substantially reduces raw material costs while aligning with green manufacturing practices. The integration of automated monitoring systems and energy-efficient technologies has enabled production facilities to cut energy consumption by 15% to 20%, offering tangible data-driven support for sustainability initiatives.

Intelligent manufacturing is reshaping the landscape of the sheet metal industry. The convergence of the Internet of Things, big data analytics, and artificial intelligence is enabling real-time production monitoring and predictive maintenance, optimizing both process performance and scheduling. Industry forecasts suggest that by 2025, the adoption rate for automated assembly and smart testing systems could reach 80% across advanced production lines worldwide. This digital transformation is setting the stage for the next generation of flexible, cost-effective, and high-quality sheet metal production.