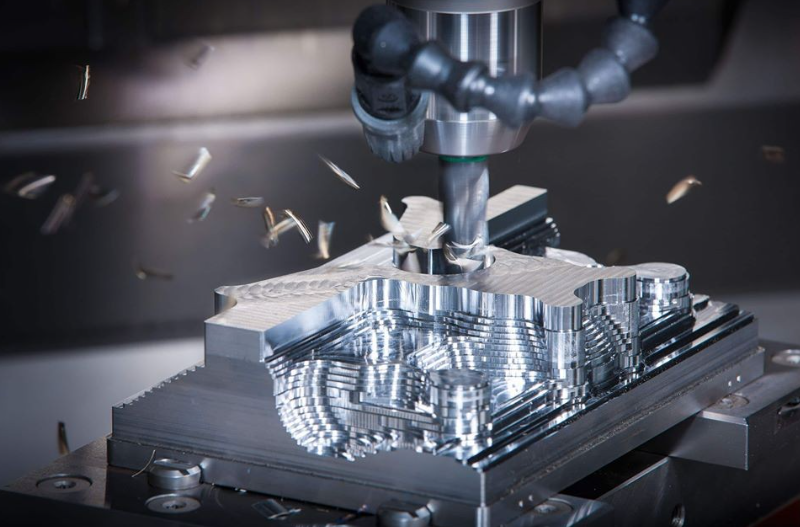

CNC machining services provide precision manufacturing solutions for industries requiring high-accuracy components. The process utilizes computer-controlled machine tools to remove material from workpieces, achieving tight tolerances and complex geometries across various materials.

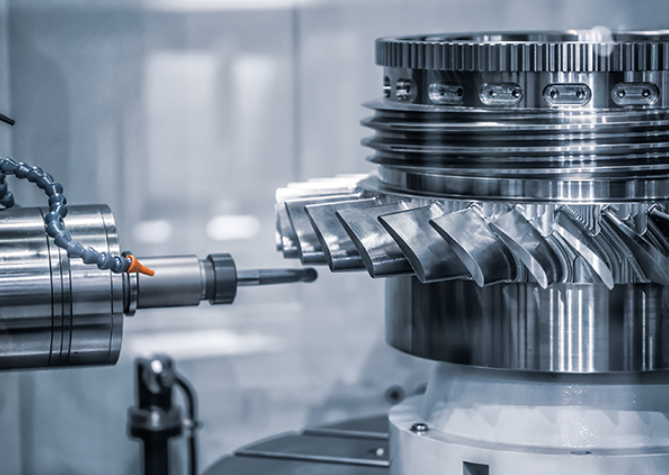

Modern CNC machining facilities operate multiple machine types to accommodate different production requirements. Three-axis vertical machining centers handle most milling operations, while five-axis models machine complex contours without repositioning. Turning centers with live tooling perform combined milling and lathe operations. Swiss-style lathes produce small, precision turned parts with diameters under 32mm. Multi-tasking machines complete entire parts in single setups through simultaneous milling, turning, and drilling operations.

Modern CNC machining facilities operate multiple machine types to accommodate different production requirements. Three-axis vertical machining centers handle most milling operations, while five-axis models machine complex contours without repositioning. Turning centers with live tooling perform combined milling and lathe operations. Swiss-style lathes produce small, precision turned parts with diameters under 32mm. Multi-tasking machines complete entire parts in single setups through simultaneous milling, turning, and drilling operations.

Material capabilities span common metals and engineering plastics. Aluminum alloys (6061, 7075) account for approximately 40% of CNC machining work due to their machinability and strength-to-weight ratio. Steel varieties (1018, 4140) serve applications requiring greater durability. Stainless steels (303, 304, 316) meet corrosion resistance needs in medical and marine environments. Titanium (Grade 2, 5) appears in aerospace and medical implants. Plastic machining includes Delrin for low-friction applications and PEEK for high-temperature resistance.

Precision standards vary by industry application. Commercial components typically maintain ±0.125mm tolerances, while aerospace and medical parts often require ±0.025mm or tighter. High-end machining centers achieve positional accuracy within 0.005mm using linear scales and thermal compensation systems. Surface finishes range from 3.2μm Ra for standard parts to 0.4μm Ra for optical components through precise toolpath strategies and specialized tooling.

CNC programming has evolved from manual G-code entry to sophisticated CAM software solutions. Modern systems automatically generate optimized toolpaths from 3D CAD models, accounting for material properties, cutting forces, and machine kinematics. Adaptive clearing strategies maintain constant tool engagement for improved tool life and reduced cycle times. Simulation modules verify programs virtually, detecting potential collisions and optimizing machining sequences before production begins.

Quality assurance systems ensure consistent output across production runs. In-process verification includes touch probes that measure workpiece features directly on the machine. Offline inspection employs coordinate measuring machines (CMMs) with 0.001mm resolution for comprehensive dimensional analysis. Surface roughness testers quantify finish quality, while optical comparators verify complex profiles. Documentation packages include first-article inspection reports, material certifications, and full dimensional inspection data for critical applications.

Production volumes range from single prototypes to mass production. Rapid prototyping services deliver machined parts within 24-72 hours using streamlined quoting and programming processes. Low-volume production (50-1,000 pieces) benefits from optimized fixturing and tooling strategies. High-volume runs exceeding 10,000 units employ dedicated production lines with automated loading systems and statistical process controls.

Industry applications demonstrate the versatility of CNC machining services. Automotive manufacturers source engine components, transmission parts, and suspension elements. Aerospace suppliers produce structural airframe components, landing gear parts, and turbine elements. Medical device companies rely on machined surgical instruments, implantable components, and diagnostic equipment parts. Electronics manufacturers utilize precision enclosures, heat sinks, and connector components.

Secondary operations complement CNC machining for finished components. Anodizing provides aluminum parts with corrosion-resistant surfaces in various colors. Powder coating offers durable finishes for steel components. Plating processes (nickel, chrome) enhance wear resistance and appearance. Heat treatment alters material properties through processes like annealing and case hardening. Laser marking adds permanent identification without affecting dimensional accuracy.

Technological advancements continue expanding service capabilities. High-speed machining centers now cut aluminum at 30,000 RPM with feed rates reaching 40m/min. Micro-machining produces features smaller than 0.1mm using specialized spindles and cutting tools. Hybrid manufacturing combines additive and subtractive processes in single machines. Digital twin technology simulates entire production processes for optimization before physical machining begins.

The CNC machining service industry maintains rigorous standards for equipment maintenance and calibration. Preventative maintenance schedules ensure machine accuracy through regular ball screw lubrication, way cover inspection, and spindle runout verification. Laser interferometers periodically measure positional accuracy across all axes. Tool management systems track cutter usage and automatically replace worn tools based on predefined life counters.

Global supply chains increasingly integrate CNC machining services for their reliability and precision. Just-in-time manufacturing arrangements synchronize production with assembly schedules. Vendor-managed inventory systems allow manufacturers to maintain stock without capital investment. Digital quoting platforms enable rapid cost estimation and order placement through automated design analysis.

Environmental considerations shape modern machining practices. Coolant mist collectors maintain air quality in machine shops. Chip processing systems separate and compact metal waste for efficient recycling. Energy-efficient spindle motors and axis drives reduce power consumption. Sustainable cutting fluid alternatives minimize environmental impact without compromising performance.

Workforce development remains critical for maintaining service quality. Machinists undergo training in CAD/CAM programming, metrology, and machine operation. Continuous education programs cover new materials, tooling technologies, and programming techniques. Cross-training enables flexibility across different machine types and production requirements.

CNC machining services continue evolving to meet emerging industry demands. The integration of artificial intelligence improves process monitoring and predictive maintenance. Advanced robotics enable lights-out manufacturing for extended production hours. Digital thread implementations connect design through production with seamless data transfer. These developments ensure CNC machining remains a cornerstone of precision manufacturing across global industries.