The production of metal stamping parts represents a fundamental manufacturing process that transforms sheet metal into precise components through mechanical deformation. This technology operates on the principle of applying controlled force to metal blanks using hardened tooling, creating parts with consistent geometries across high-volume production runs. The origins of modern stamping trace back to the late 19th century when the bicycle industry first adopted mass production techniques, later perfected by automotive manufacturers in the early 20th century.

Metal stamping processes begin with coil or blank stock preparation, where sheet metal undergoes precise cutting to required dimensions. Steel coils typically range from 0.5mm to 6mm in thickness for most stamping applications, with widths up to 2 meters for automotive panel production. The material selection process considers multiple factors including tensile strength (ranging from 270 MPa for mild steel to 1500 MPa for advanced high-strength steels), formability characteristics, and corrosion resistance requirements. Aluminum alloys have gained increasing adoption in recent years, particularly in transportation applications where weight reduction proves critical.

Metal stamping processes begin with coil or blank stock preparation, where sheet metal undergoes precise cutting to required dimensions. Steel coils typically range from 0.5mm to 6mm in thickness for most stamping applications, with widths up to 2 meters for automotive panel production. The material selection process considers multiple factors including tensile strength (ranging from 270 MPa for mild steel to 1500 MPa for advanced high-strength steels), formability characteristics, and corrosion resistance requirements. Aluminum alloys have gained increasing adoption in recent years, particularly in transportation applications where weight reduction proves critical.

Press selection constitutes a fundamental consideration in stamping operations. Mechanical presses dominate high-speed production with capabilities exceeding 1,200 strokes per minute for simple blanking operations, while hydraulic presses provide superior force control for complex forming sequences. Servo-electric presses represent the latest technological advancement, offering programmable slide motion with energy savings up to 30% compared to conventional systems. Press tonnage requirements vary significantly by application – small electronic components may require only 20 tons, while automotive frame parts demand presses exceeding 2,500 tons capacity.

Tooling design represents the most technically demanding aspect of metal stamping. Progressive dies, the most common tooling configuration, incorporate multiple stations that perform successive operations as the strip metal feeds through the press. A typical progressive die might include:

- Pilot holes for precise material positioning

- Pierce stations creating functional holes to ±0.025mm tolerance

- Forming stations bending material at precisely calculated radii

- Cut-off operations separating finished parts from the carrier strip

Tool steel selection depends on production volume and material hardness, with D2 tool steel common for 500,000-part runs and tungsten carbide inserts extending tool life beyond 5 million cycles for high-volume applications. Modern tooling incorporates sophisticated features such as nitrogen-assisted stripper plates for clean material release and sensor-equipped die protection systems that detect misfeeds with 0.1mm sensitivity.

The stamping process itself involves complex material behavior that requires careful engineering control. When forming mild steel, the material typically undergoes 20-30% thinning in critical bend areas before reaching failure limits. Advanced simulation software predicts these deformation patterns using finite element analysis, allowing engineers to optimize blank shapes and form sequences before cutting production tooling. The software accounts for material properties including n-values (strain hardening coefficients) and r-values (anisotropy ratios) that significantly influence formability.

Quality control systems ensure stamped parts meet dimensional specifications. In-process measurement devices monitor critical features with 0.01mm resolution, while coordinate measuring machines (CMMs) verify final part geometry against CAD models. Optical comparators provide rapid inspection of profile dimensions, particularly for small, high-volume components. Statistical process control methods track key variables including press tonnage, material thickness, and dimensional drift, maintaining process capability indices (Cpk) above 1.33 for production runs.

Secondary operations frequently complement the stamping process. Vibratory deburring removes sharp edges with media selected for specific material and edge quality requirements. Heat treatment processes such as annealing or tempering adjust material properties when stamped parts require enhanced strength or ductility. Surface finishing options range from electroplating for corrosion resistance to powder coating for decorative applications, each adding 0.02-0.1mm to part dimensions.

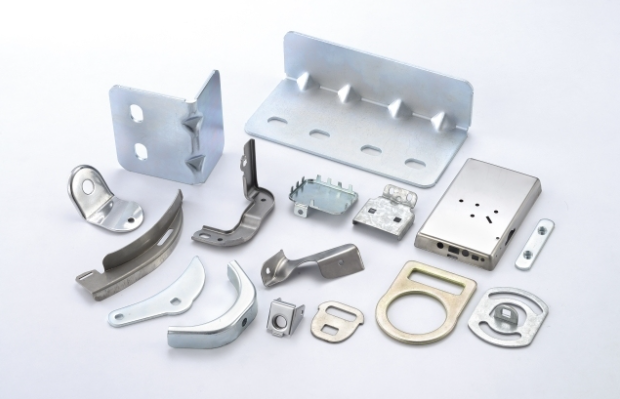

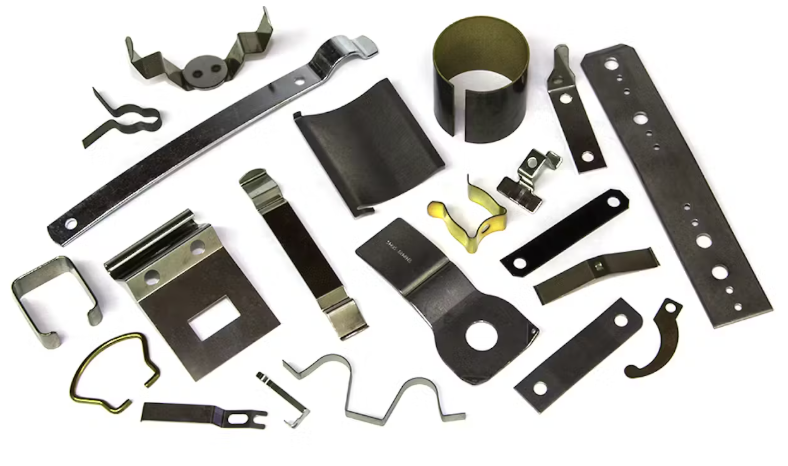

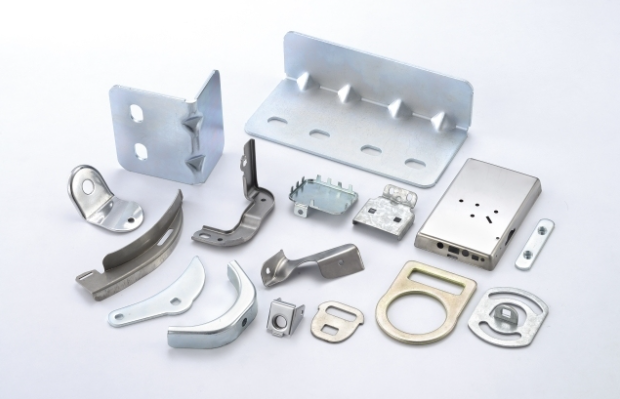

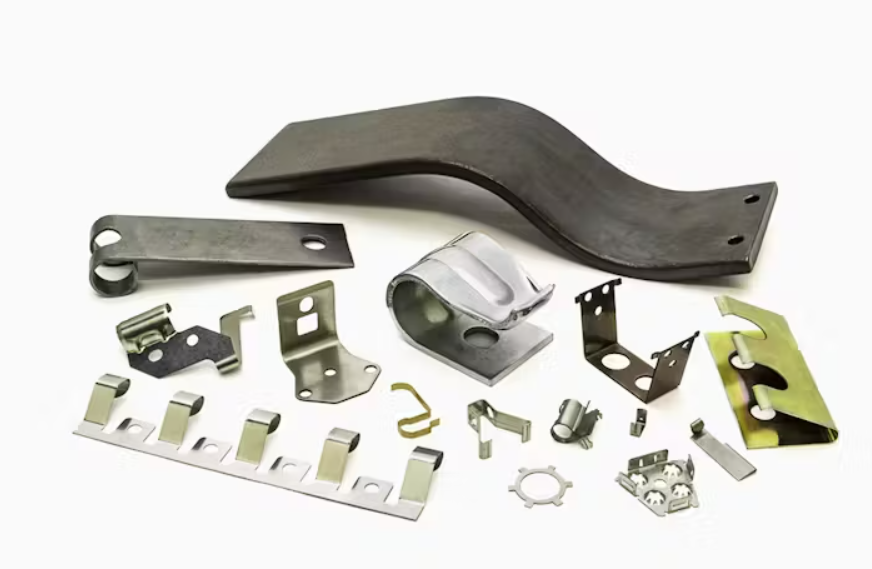

Industrial applications of metal stamping span multiple sectors. Automotive manufacturers utilize stamping for body panels, structural components, and underbody parts, with a typical vehicle containing 300-500 stamped steel parts. Electronics manufacturers rely on precision stamping for connector pins, shielding cans, and heat sink components where tolerances below ±0.05mm are common. The appliance industry consumes millions of stamped parts annually for enclosures, brackets, and functional components requiring consistent quality at low unit costs.

Recent technological advancements continue to expand stamping capabilities. Advanced high-strength steels (AHSS) with tensile strengths exceeding 1000 MPa challenge traditional forming limits, requiring innovative tooling solutions and press technologies. Hot stamping processes heat boron steel blanks to 900°C before forming, then rapidly quench them in the die to achieve 1500 MPa tensile strength for automotive safety components. Smart tooling systems incorporate embedded sensors that monitor wear and process conditions in real time, predicting maintenance needs before quality issues arise.

Economic considerations drive stamping process optimization. Material utilization frequently reaches 85-95% through sophisticated nesting software that arranges parts to minimize scrap. Quick-change die systems reduce setup times from hours to minutes, improving press utilization in job shop environments. Automated material handling systems feed coils weighing up to 50 tons into presses without operator intervention, enabling lights-out production for high-volume components.

Environmental aspects of metal stamping have gained increasing attention. Scrap recycling rates approach 100% for ferrous materials, with reprocessing energy requirements approximately 75% lower than primary steel production. Water-based lubricants have largely replaced petroleum-based compounds in forming operations, reducing volatile organic compound emissions. Energy recovery systems capture press brake energy during deceleration, converting it to usable power for other plant operations.

Workforce requirements reflect the technical sophistication of modern stamping operations. Press operators now require skills in computerized control systems and basic troubleshooting, while tool and die makers maintain expertise in precision machining and metallurgy. Simulation engineers combine materials knowledge with advanced software skills to optimize forming processes before physical trials. This evolving skill set has prompted development of specialized training programs combining classroom instruction with hands-on press operation.

Future developments in metal stamping focus on several key areas. The integration of artificial intelligence for process monitoring promises to reduce scrap rates through real-time adjustment of press parameters. 3D printing of conformal cooling channels in die components improves thermal management during high-speed production. Continued development of ultra-high-strength materials will drive innovations in forming technologies to maintain manufacturing feasibility while meeting increasingly stringent performance requirements.

The metal stamping industry maintains its position as a cornerstone of modern manufacturing by continuously adapting to new materials, technologies, and market demands. This process combines century-old mechanical principles with cutting-edge control systems to produce components that meet the precision, strength, and cost requirements of today’s industrial applications. The ongoing evolution of stamping technology ensures its continued relevance across diverse sectors from microelectronics to heavy vehicle production.