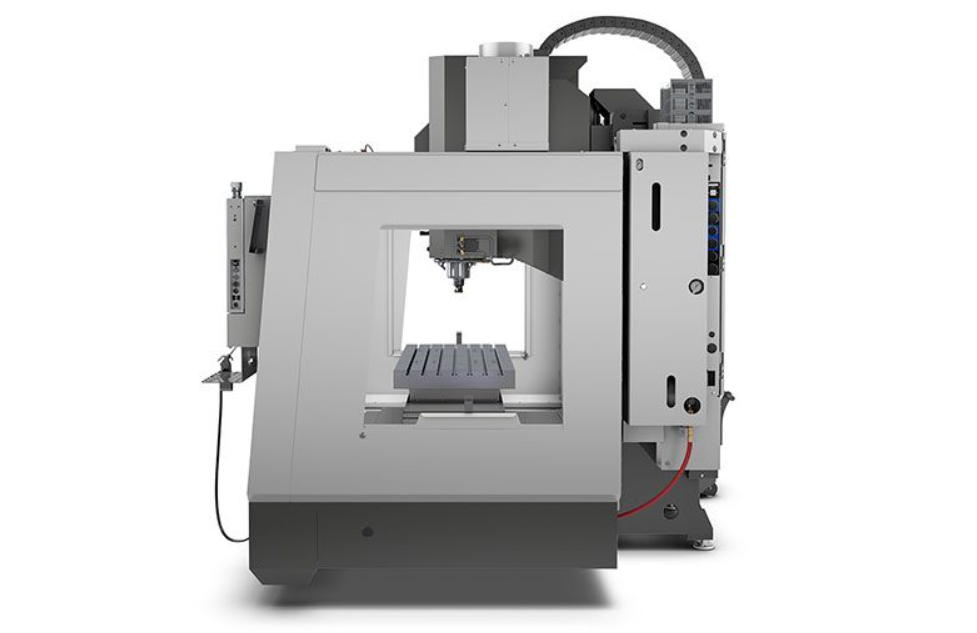

The VF-3SS-V represents HAAS’s enhanced super-speed machining solution, delivering 50% faster rapids and 20% higher acceleration than standard VF models. This rigid-frame vertical mill features a 30-tool side-mount changer and 12,000rpm inline direct-drive spindle for high-productivity machining.

Key Performance Characteristics

- Rapid Traverse: 1,524 ipm (38.7 m/min)

- Spindle Speed: 12,000 rpm (15 hp/11.2 kW continuous)

- Tool Change Time: 1.2 seconds chip-to-chip

- Positioning Accuracy: ±0.0002″ (±0.005 mm)

- Control System: Next Generation HAAS CNC with 15″ touchscreen

Structural Features

Structural Features

1. Enhanced Frame Design

- Cast Iron Construction: 30% more mass than standard VF-3

- Box-Way Guides: Y-axis 55mm, Z-axis 65mm hardened steel

- Thermal Compensation: Active cooling on ballscrews

2. High-Performance Spindle

- Inline Direct Drive: Eliminates gearbox maintenance

- 30HP (22.4kW) Peak: 15HP (11.2kW) continuous

- Torque: 166 ft-lb (225 Nm) at 1,200 rpm

3. Super-Speed Motion System

- Acceleration: 0.6G (5.88 m/s²)

- Servo Motors: 40% more powerful than standard

- Preloaded Ballscrews: C3 grade precision

Technical Specifications

| Parameter | Metric | Imperial |

|---|---|---|

| X/Y/Z Travel | 762 × 406 × 508 mm | 30 × 16 × 20 in |

| Table Size | 1,219 × 381 mm | 48 × 15 in |

| Max Table Load | 1,000 kg | 2,200 lbs |

| Spindle Nose | CAT-40 | CAT-40 |

| Tool Capacity | 30 tools | 30 tools |

| Machine Weight | 5,670 kg | 12,500 lbs |

| Power Requirement | 30 kVA | 30 kVA |

Automation Options

1. Pallet Systems

- 160 mm dual-station rotary

- 400 mm linear pallet changer

2. Probing Packages

- Wireless workpiece inspection

- Tool breakage detection

- Tool length and diameter measurement

3. Coolant Systems

- 300 psi (20 bar) through-spindle

- Programmable coolant nozzle

- Chip conveyor standard

Industry Applications

1. Aerospace Components

- Aluminum structural parts

- Titanium fittings

- Composite tooling

2. Automotive Production

- Engine blocks

- Transmission cases

- Suspension components

3. Medical Device Manufacturing

- Orthopedic implants

- Surgical instruments

- Dental components

Maintenance Requirements

Daily Checks

- Way lube levels

- Coolant concentration

- Chip accumulation

Monthly Service

- Way cover inspection

- Spindle runout verification

- Filter replacement

Annual Maintenance

- Ballscrew recalibration

- Way wiper replacement

- Complete electrical check

Installation Specifications

- Floor Space: 2,438 × 2,743 mm (96 × 108 in)

- Foundation: 6″ reinforced concrete minimum

- Power: 240/480V 3-phase, 60 Hz

- Air Supply: 100 psi (6.9 bar) clean, dry air

- Ambient Temperature: 10-35°C (50-95°F)