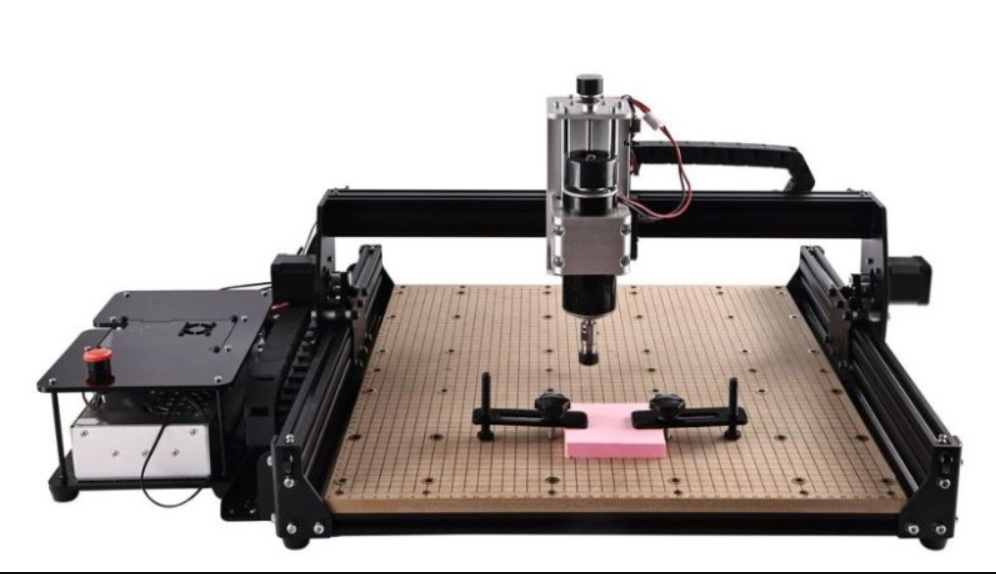

A CNC device is a computer-controlled machine tool used to cut, shape, and finish materials like metal, wood, and plastic. The term “CNC” stands for Computer Numerical Control, which means the machine follows pre-programmed instructions to perform its tasks with incredible precision.

Why CNC Devices Matter

- Precision: CNC devices can achieve tolerances as tight as ±0.0005 inches (0.0127 mm).

- Efficiency: They can run 24/7 with minimal supervision, speeding up production.

- Versatility: CNC devices work with a wide range of materials, from metals to plastics and wood.

At its core, a CNC device is all about turning digital designs into physical objects. Here’s a step-by-step look at how the process works:

1. Designing the Part

The process begins with a 3D CAD model, created using software like SolidWorks, Fusion 360, or AutoCAD. This digital design is like a blueprint, detailing every dimension and feature of the part.

- Pro Tip: Use CAM software to optimize toolpaths and reduce machining time. Popular options include Mastercam and Fusion 360.

2. Converting the Design into Instructions

Once the design is complete, it’s converted into G-code, a language that tells the CNC device how to move. G-code includes instructions for everything from tool speed to cutting depth.

- Example: A simple G-code command might tell the machine to move the cutting tool to a specific position and start cutting.

3. Setting Up the Machine

Before machining begins, the operator sets up the machine by loading the material, securing it in place, and installing the appropriate cutting tools. This step is crucial for ensuring accuracy and safety.

- Real-World Example: A manufacturer setting up a CNC device to produce custom car parts would carefully align the material and tools to ensure precise cuts.

4. Machining the Part

With everything in place, the CNC device follows the G-code instructions to cut, shape, and finish the material. The machine moves the cutting tool along multiple axes (typically X, Y, and Z) to create the desired shape.

- Fun Fact: Some CNC devices can move along five or more axes, allowing them to create incredibly complex shapes.

5. Finishing and Inspection

After machining, the part may undergo finishing processes like sanding, polishing, or coating. Inspection tools like CMMs (Coordinate Measuring Machines) ensure that the part meets the required specifications.

Why CNC Devices are Essential in Modern Manufacturing

1. Precision and Accuracy

CNC devices are known for their ability to achieve extremely tight tolerances. For example, in the aerospace industry, CNC devices are used to create turbine blades and engine components that require micron-level precision.

2. Increased Efficiency

CNC devices can run 24/7 with minimal supervision, significantly speeding up production. A 2021 study by Modern Machine Shop found that companies using CNC devices saw a 25% increase in production efficiency compared to manual methods.

3. Cost Savings

While the initial investment in a CNC device can be high, the long-term savings are substantial. By reducing material waste and labor costs, CNC machining can lower production expenses by up to 20%, according to a 2020 analysis by Manufacturing Global.

4. Versatility

CNC devices work with a wide range of materials, making them ideal for industries like automotive, aerospace, and medical devices.

Applications of CNC Devices

1. Automotive Industry

CNC devices are used to create critical components like engine blocks, transmission cases, and suspension parts. For example, Tesla relies on CNC machining to produce high-precision components for its electric vehicles.

2. Aerospace Industry

The aerospace sector uses CNC devices to manufacture lightweight, high-strength parts like turbine blades and fuselage frames. Boeing, for instance, uses CNC devices to produce components for its 787 Dreamliner.

3. Medical Devices

CNC devices are essential for developing surgical instruments, implants, and prosthetics. A 2023 case study by Medical Design & Outsourcing highlighted how a company used CNC machining to reduce the development time of a new prosthetic limb by 30%.

4. Consumer Electronics

From smartphones to wearables, CNC devices help electronics companies test and refine their designs. Apple, for example, uses CNC devices to perfect the fit and finish of its devices.

Challenges and Limitations

1. High Initial Cost

CNC devices can be expensive, with prices ranging from $50,000 for basic models to over $500,000 for advanced systems. However, many companies opt for outsourcing to reduce costs.

2. Skilled Labor Required

Operating a CNC device requires specialized training. According to a 2021 article by IndustryWeek, there’s a growing skills gap in the manufacturing sector, with many companies struggling to find qualified CNC operators.

3. Material Waste

CNC machining is a subtractive process, meaning it generates material waste. For complex designs, this can result in significant scrap.

The Future of CNC Devices

1. Smart Manufacturing

The integration of IoT (Internet of Things) and AI (Artificial Intelligence) is revolutionizing CNC machining. For example, predictive maintenance systems use AI to monitor tool wear and optimize machining parameters in real-time.

2. Hybrid Machining

Combining additive manufacturing (3D printing) with CNC machining allows for the creation of complex geometries with minimal waste. Hybrid machines are becoming increasingly popular in industries like aerospace and medical devices.

3. Advanced Materials

New materials, such as high-performance polymers and metal composites, are expanding the possibilities for CNC machining.

Conclusion

So, what is a CNC device? It’s a powerful tool that turns digital designs into physical objects with incredible precision and efficiency. From cars to medical devices, CNC devices are the backbone of modern manufacturing, enabling the production of high-quality parts that meet the demands of today’s industries.

If you’re considering investing in CNC technology, now is the time. With advancements in smart manufacturing and hybrid technologies, the future of CNC devices is brighter than ever. Whether you’re a small business owner or a large manufacturer, CNC devices can help you stay ahead of the competition.