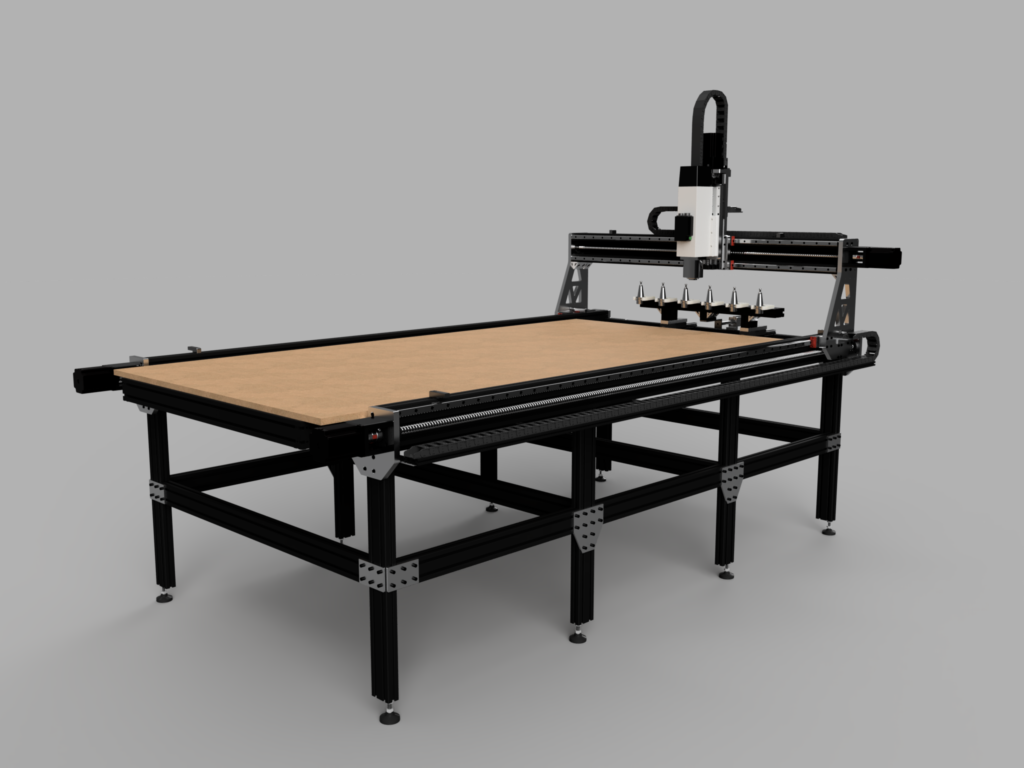

4×8 CNC Router are the go-to machines for industries that require large-scale precision cutting, carving, and shaping of materials like wood, plastic, and composites. With a cutting area of 4 feet by 8 feet (1220 mm x 2440 mm), these machines are ideal for producing everything from furniture and cabinetry to signage and architectural components. But what makes 4×8 CNC router so powerful, and how do they work? Let’s dive into the fascinating world of CNC routing and explore its impact on modern manufacturing.

What Are 4×8 CNC Router?

A 4×8 CNC Router is a computer-controlled machine that uses rotating cutting tools to remove material from a workpiece. The term “4×8” refers to the machine’s cutting area, which is 4 feet by 8 feet (1220 mm x 2440 mm). This large working area makes it ideal for handling full-sized sheets of material, such as plywood, MDF, and acrylic.

Why 4×8 CNC Router Matter

- Large Cutting Area: Perfect for handling full-sized sheets of material.

- Precision: CNC router can achieve tolerances as tight as ±0.005 inches (0.127 mm).

- Efficiency: Automated processes reduce human error and increase production speed.

- Versatility: CNC router work with a wide range of materials and can perform complex cuts and carvings.

How Do 4×8 CNC Router Work?

How Do 4×8 CNC Router Work?

Let’s break down the process step by step, with a focus on the technical details that make CNC routing so effective.

1. Design: The Blueprint

The process begins with a 3D model of the part, created using CAD (Computer-Aided Design) software. This digital blueprint is the foundation for everything that follows.

- Pro Tip: Use software like SolidWorks, Fusion 360, or AutoCAD to create detailed and accurate models. And don’t forget to consider manufacturability—designing for CNC routing can save you a lot of headaches down the line.

2. Material Selection: Choosing the Right Stuff

The material you choose can make or break your project. Common options include:

- Wood: Hardwood (durable and aesthetically pleasing), plywood (affordable and versatile), MDF (easy to machine).

- Plastics: Acrylic (clear and impact-resistant), polycarbonate (strong and durable), PVC (lightweight and easy to cut).

- Metals: Aluminum (lightweight and easy to machine), brass (decorative and corrosion-resistant).

- Composites: Carbon fiber (lightweight and strong), fiberglass (durable and corrosion-resistant).

- Did You Know? MDF (Medium-Density Fiberboard) is one of the most popular materials for CNC routing because it’s easy to machine and provides a smooth finish.

3. CNC Routing: The Art of Cutting

This is where the magic happens. The CNC routing process involves moving a rotating cutting tool across the workpiece to remove material. Here’s a quick rundown of the main steps:

- Setup: The workpiece is secured to the worktable using clamps or vacuum hold-downs.

- Programming: The operator inputs the G-code instructions into the control panel.

- Machining: The spindle rotates the cutting tool, and the machine moves it along the X, Y, and Z axes to create the desired shape.

- Finishing: The machine performs multiple passes to achieve the desired dimensions and surface finish.

- Fun Fact: A high-performance CNC router can achieve spindle speeds of up to 24,000 RPM, allowing for ultra-smooth finishes.

G-Code Example for CNC Routing

Here’s an example of G-code for a CNC routing operation:

This code tells the machine to move to the coordinates (X50, Y50, Z10), then perform a cutting operation at a feed rate of 100 mm/min.

4. Finishing: The Final Touch

Once the routing is done, the part may undergo additional processes to improve its appearance and functionality. This could include:

- Sanding: To smooth out rough edges.

- Polishing: To achieve a mirror-like finish.

- Painting or Coating: To protect the part from wear or enhance its appearance.

Why Are 4×8 CNC Router So Important?

1. Large-Scale Production

4×8 CNC router are ideal for handling full-sized sheets of material, making them perfect for large-scale production. For example, in the furniture industry, 4×8 CNC router are used to produce components for cabinets, tables, and chairs. According to a 2022 report by Furniture Today, CNC routing has increased production efficiency in the furniture industry by over 30%.

2. Precision and Accuracy

4×8 CNC routers are known for their ability to achieve extremely tight tolerances. For example, in the signage industry, CNC router are used to create precise and intricate designs for signs and displays. A 2023 case study by Signs of the Times highlighted how a company used CNC routing to reduce the production time of custom signs by 50%.

3. Cost-Effectiveness

While the initial investment in a 4×8 CNC router can be high, the long-term savings are substantial. By reducing material waste and labor costs, CNC routing can lower production expenses by up to 20%, according to a 2020 analysis by Manufacturing Global.

4. Versatility

4×8 CNC router work with a wide range of materials, making them ideal for industries like woodworking, signage, and aerospace. Whether you need a decorative wooden panel or a precision-cut metal component, CNC routing has you covered.

Real-World Applications of 4×8 CNC Router

1. Furniture Manufacturing

4×8 CNC router are used to create furniture components like cabinets, tables, and chairs. For example, IKEA uses 4×8 CNC router to produce high-precision components for its furniture.

2. Signage

4×8 CNC router are essential for creating signs and displays. A 2023 case study by Signs of the Times highlighted how a company used CNC routing to reduce the production time of custom signs by 50%.

3. Architectural Components

The construction industry relies heavily on 4×8 CNC router to create architectural components like wall panels, doors, and windows. For instance, a 2021 report by Architectural Digest noted that CNC routing has revolutionized the production of custom architectural elements.

4. Prototyping

4×8 CNC router are widely used in prototyping to create accurate and functional models. For example, Tesla uses CNC router to prototype new components for its electric vehicles.

Challenges and Limitations

1. High Initial Cost

4×8 CNC router can be expensive, with prices ranging from $20,000 for basic models to over $200,000 for advanced systems. However, many companies opt for outsourcing to reduce costs.

2. Skilled Labor Required

Operating a 4×8 CNC router requires specialized training. According to a 2021 article by IndustryWeek, there’s a growing skills gap in the manufacturing sector, with many companies struggling to find qualified CNC operators.

3. Material Constraints

While 4×8 CNC router can handle a wide range of materials, some (like hardened steel or titanium) require specialized tools and slower machining speeds, which can increase costs.

The Future of 4×8 CNC Router

The future of 4×8 CNC router is looking bright, with several exciting trends on the horizon:

1. Automation and Robotics

The integration of CNC router with robotic arms is revolutionizing manufacturing. For example, Fanuc has developed robotic systems that can load and unload CNC router, further reducing labor costs and increasing efficiency.

2. AI and Machine Learning

Artificial intelligence is being used to optimize CNC routing processes. A 2023 report by TechCrunch highlighted how AI algorithms can predict tool wear and adjust machining parameters in real-time, reducing downtime and improving accuracy.

3. Additive Manufacturing (3D Printing)

While CNC routing is a subtractive process, it’s increasingly being combined with additive manufacturing. Hybrid machines that can both 3D print and CNC route are becoming more common, offering the best of both worlds.

Wrapping It Up

4×8 CNC router are the unsung heroes of modern manufacturing, enabling the production of high-precision, complex components with unmatched efficiency. From furniture to architectural components, these machines play a crucial role in shaping the world around us. While they come with challenges like high costs and the need for skilled labor, the benefits far outweigh the drawbacks.

If you’re considering investing in a 4×8 CNC router, it’s important to weigh your options carefully. Look for a machine that meets your specific needs, whether it’s a basic 3-axis router or a high-end 5-axis system. And don’t forget to factor in the cost of training your team to operate it effectively.

At the end of the day, a 4×8 CNC router isn’t just a tool—it’s an investment in the future of your business. So, what will you create with it?

References

- Furniture Today (2022) – Report on CNC routing in furniture manufacturing.

- Signs of the Times (2023) – Case study on CNC routing for signage.

- Manufacturing Global (2020) – Analysis of cost savings with CNC routing.

- IndustryWeek (2021) – Article on the skills gap in CNC machining.

- TechCrunch (2023) – Report on AI in CNC routing operations.