Let’s talk about something that doesn’t always get the spotlight but is absolutely essential to how the modern world works: Metal CNC Machines. These machines are the quiet workhorses behind everything from the car you drive to the phone in your pocket. They’re not just tools—they’re the backbone of precision manufacturing. So, what makes them so special, and why should you care? Let’s break it down.

What’s the Big Deal About Metal CNC Machines?

At their core, Metal CNC Machines are computer-controlled tools that cut, shape, and finish metal parts with incredible accuracy. Think of them as the ultimate multitaskers: they can drill, mill, turn, and even polish metal into almost any shape you can imagine. And the best part? They do it all automatically, following digital instructions (called G-code) to the letter.

But here’s where it gets interesting: CNC machines aren’t just about precision. They’re also about speed, efficiency, and versatility. Whether you’re making a single prototype or churning out thousands of parts, these machines can handle it—and do it faster and more accurately than any human ever could.

How Do They Actually Work?

Okay, let’s get a little technical—but not too much. Here’s the basic process:

- Design: Someone creates a 3D model of the part using CAD software. This is like the blueprint for what the machine will make.

- Programming: The CAD file gets converted into G-code, which is essentially a set of instructions for the machine. It tells the machine where to move, how fast to go, and what tools to use.

- Setup: The metal workpiece is clamped down, and the right tools (like drills or end mills) are loaded into the machine.

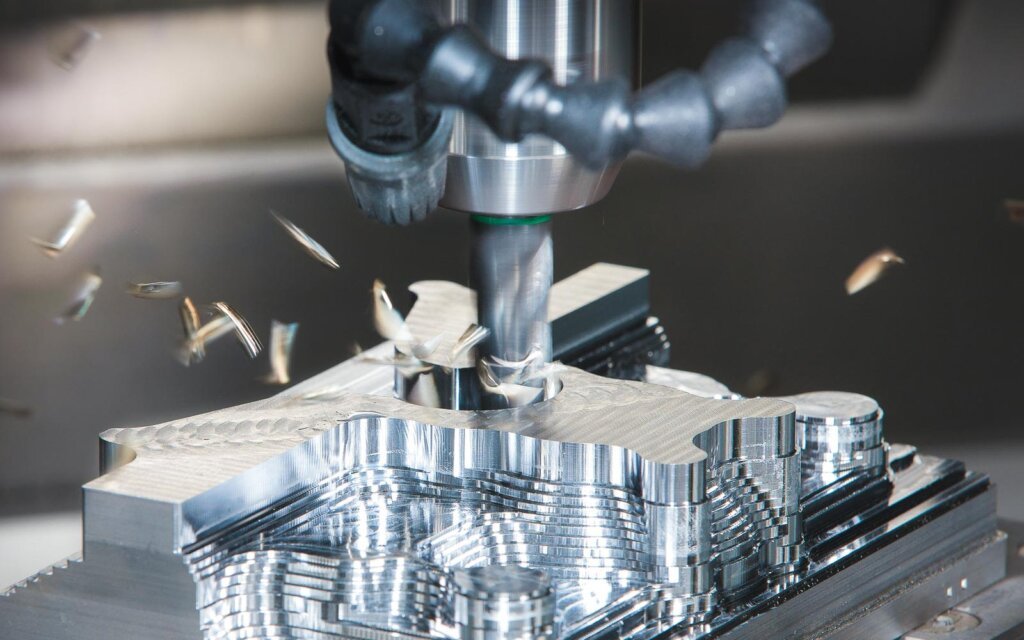

- Machining: The machine gets to work, cutting away material to create the part. It’s like a sculptor, but instead of chisels, it uses spinning tools that can slice through metal like butter.

- Finishing: Once the part is done, it might get polished, deburred, or coated to make it look and function just right.

Different Types for Different Jobs

Not all CNC machines are created equal. Here are a few common types:

- CNC Mills: Great for cutting and drilling. They’re like the Swiss Army knives of CNC machines.

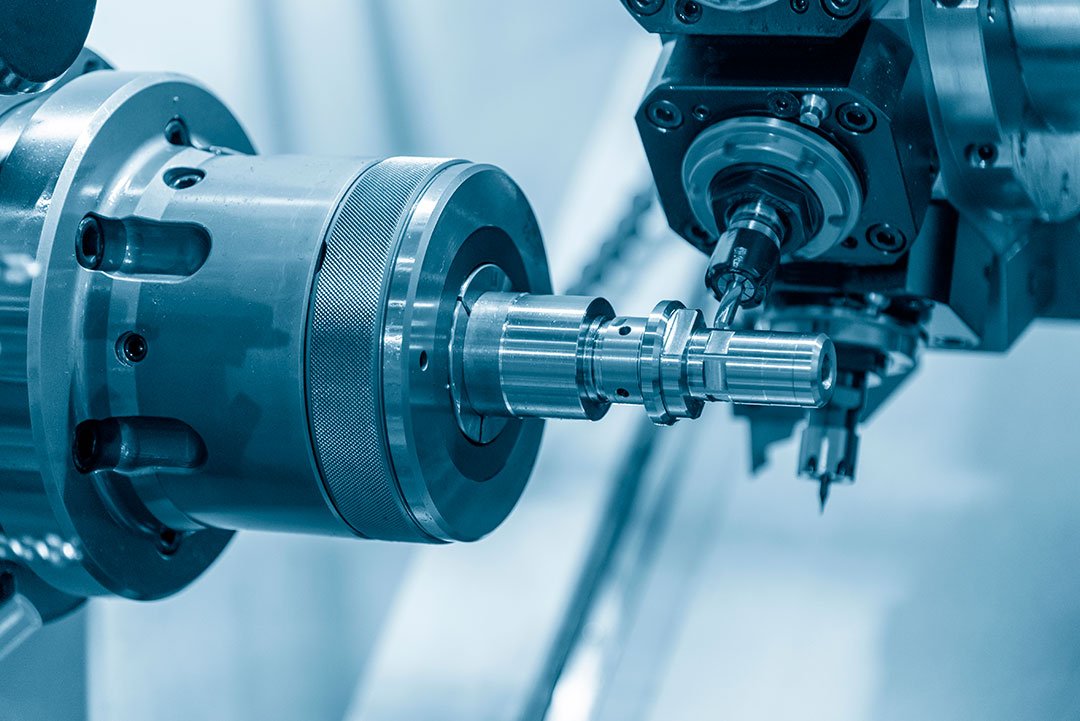

- CNC Lathes: Perfect for cylindrical parts. The workpiece spins while a stationary tool shapes it.

- 5-Axis Machines: These are the rock stars of CNC machining. They can move in five directions at once, making them ideal for super complex parts.

Why Are They So Important?

1. Precision That’s Out of This World

When it comes to making parts, precision is everything. And CNC machines deliver. For example, in the aerospace industry, where even a tiny mistake can be disastrous, CNC machines are used to create components like turbine blades and engine parts. According to a 2021 report by Aerospace Manufacturing and Design, CNC machining has reduced error rates in aerospace manufacturing by over 50%. That’s a big deal when you’re building something that flies at 30,000 feet.

2. Speed and Efficiency

Time is money, and CNC machines save a lot of both. They can run 24/7 with minimal supervision, which means faster production times and lower labor costs. A 2020 study by Modern Machine Shop found that companies using CNC machines saw a 30% increase in production efficiency compared to traditional methods. That’s like getting an extra day’s worth of work out of every week.

3. Cost-Effectiveness

Yes, CNC machines can be expensive—some high-end models cost over $500,000. But here’s the thing: they pay for themselves in the long run. By reducing material waste and labor costs, CNC machining can lower production expenses by up to 20%, according to a 2019 analysis by Manufacturing Global. Plus, they’re incredibly versatile, so you can use the same machine for a wide range of projects.

4. Flexibility

One of the coolest things about CNC machines is how adaptable they are. With just a change in the G-code, the same machine can go from making car parts to medical implants. This flexibility is a game-changer for industries like automotive and healthcare, where customization is key.

Where Are They Used?

1. Automotive Industry

From engine blocks to custom car parts, CNC machines are everywhere in the automotive world. Tesla, for example, uses CNC machining to produce precision components for its electric vehicles. The result? Cars that are not only high-performance but also incredibly reliable.

2. Aerospace Industry

The aerospace sector relies heavily on CNC machines to create lightweight, high-strength parts. Boeing, for instance, uses 5-axis CNC machines to manufacture complex aircraft components like wing spars and landing gear. These parts have to be perfect, and CNC machines deliver.

3. Medical Devices

CNC machining is also a big deal in the medical field. It’s used to make everything from surgical instruments to implants and prosthetics. A 2022 case study by Medical Design & Outsourcing highlighted how a medical device company reduced production time by 40% using CNC machines. That means faster turnaround times for life-saving equipment.

4. Consumer Electronics

Ever wondered how your smartphone’s aluminum casing is made? CNC machines are the answer. Companies like Apple use CNC machining to create the sleek, seamless designs of their MacBooks and iPhones. It’s a perfect example of how CNC machines combine precision with aesthetics.

What Are the Challenges?

1. High Initial Cost

Let’s be real: CNC machines aren’t cheap. A basic 3-axis mill can cost around $50,000, while a high-end 5-axis machine can set you back half a million dollars or more. But as we’ve seen, the long-term savings often make it worth the investment.

2. Skilled Labor Required

Operating a CNC machine isn’t something you can learn overnight. It takes specialized training, and there’s a growing skills gap in the manufacturing sector. According to a 2021 article by IndustryWeek, many companies are struggling to find qualified CNC operators. That’s something to keep in mind if you’re thinking about investing in a CNC machine.

3. Material Constraints

While CNC machines can handle a wide range of metals, some materials (like hardened steel or titanium) require specialized tools and slower machining speeds. This can increase costs and production times, so it’s important to plan accordingly.

What’s Next for Metal CNC Machines?

The future of CNC machining is looking pretty exciting. Here are a few trends to watch:

1. Automation and Robotics

The integration of CNC machines with robotic arms is changing the game. For example, Fanuc, a leading robotics company, has developed robotic systems that can load and unload CNC machines, further reducing labor costs and increasing efficiency.

2. AI and Machine Learning

Artificial intelligence is starting to play a role in CNC machining. A 2023 report by TechCrunch highlighted how AI algorithms can predict tool wear and adjust machining parameters in real-time. This not only reduces downtime but also improves accuracy.

3. Additive Manufacturing (3D Printing)

While CNC machining is a subtractive process (removing material to create a part), it’s increasingly being combined with additive manufacturing. Hybrid machines that can both 3D print and CNC mill are becoming more common, offering the best of both worlds.

Wrapping It Up

Metal CNC machines are more than just tools—they’re the foundation of modern manufacturing. They’re fast, precise, and incredibly versatile, making them indispensable in industries like automotive, aerospace, and healthcare. Sure, they come with challenges like high costs and the need for skilled labor, but the benefits far outweigh the drawbacks.

If you’re thinking about investing in a metal CNC machine, take the time to research your options. Look for a machine that fits your needs, whether it’s a basic 3-axis mill or a high-end 5-axis system. And don’t forget to invest in training for your team—because even the best machine is only as good as the person operating it.

At the end of the day, a metal CNC machine isn’t just a piece of equipment. It’s a way to push the boundaries of what’s possible in manufacturing. So, what will you create with it?

References

- Aerospace Manufacturing and Design (2021) – Report on CNC machining in aerospace.

- Modern Machine Shop (2020) – Study on production efficiency with CNC machines.

- Manufacturing Global (2019) – Analysis of cost savings with CNC machining.

- Medical Design & Outsourcing (2022) – Case study on CNC machining for medical devices.

- IndustryWeek (2021) – Article on the skills gap in CNC machining.

- TechCrunch (2023) – Report on AI in CNC machining.

- Fanuc Robotics – Information on CNC machine automation.