When it comes to creating complex, high-precision parts, 5-Axis CNC Machines are the gold standard. These machines are the workhorses of industries like aerospace, automotive, and medical devices, where even the smallest error can have serious consequences. But what exactly makes them so special? Let’s dive into what 5-axis CNC machines are, how they work, and why they’re revolutionizing modern manufacturing.

What is a 5-Axis CNC Machine?

A 5-Axis CNC Machine is a computer-controlled tool that can move a cutting tool or workpiece in five different directions simultaneously. Unlike traditional 3-axis machines, which only move in the X, Y, and Z axes, 5-axis machines add two rotational axes (A and B or C) to the mix. This allows them to create incredibly complex shapes and features in a single setup.

Why Should You Care?

- Complexity: Create parts with intricate geometries that would be impossible with 3-axis machines.

- Precision: Achieve tolerances as tight as ±0.0005 inches (0.0127 mm).

- Efficiency: Reduce setup time and increase production speed.

- Versatility: Work with a wide range of materials, from aluminum to titanium.

How Does a 5-Axis CNC Machine Work?

To understand how a 5-axis CNC machine works, let’s break it down into its main components and movements:

1. The Five Axes

- X, Y, Z: These are the linear axes that move the cutting tool or workpiece in three dimensions.

- A and B (or C): These are the rotational axes that allow the tool or workpiece to tilt and rotate, enabling complex cuts from multiple angles.

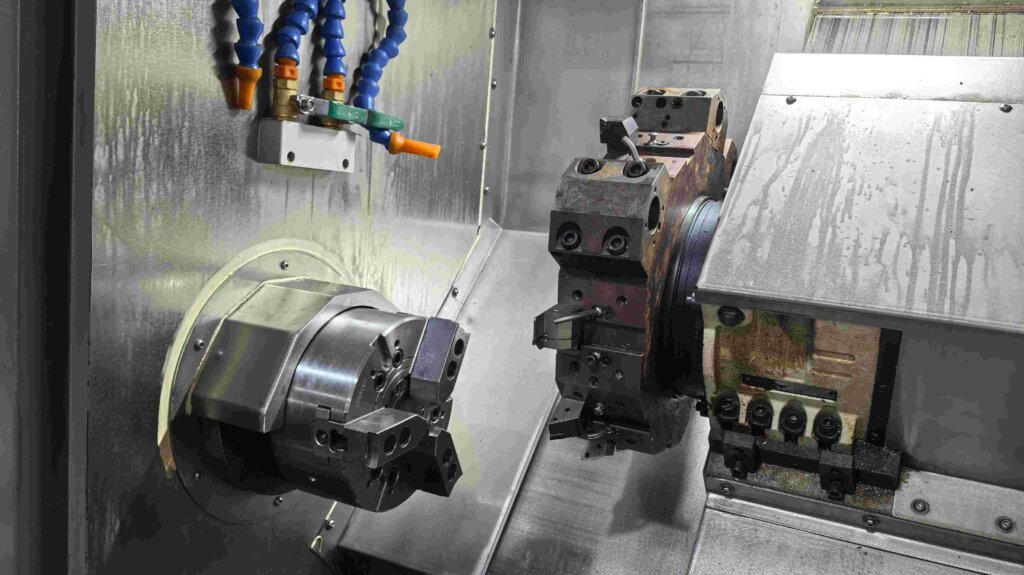

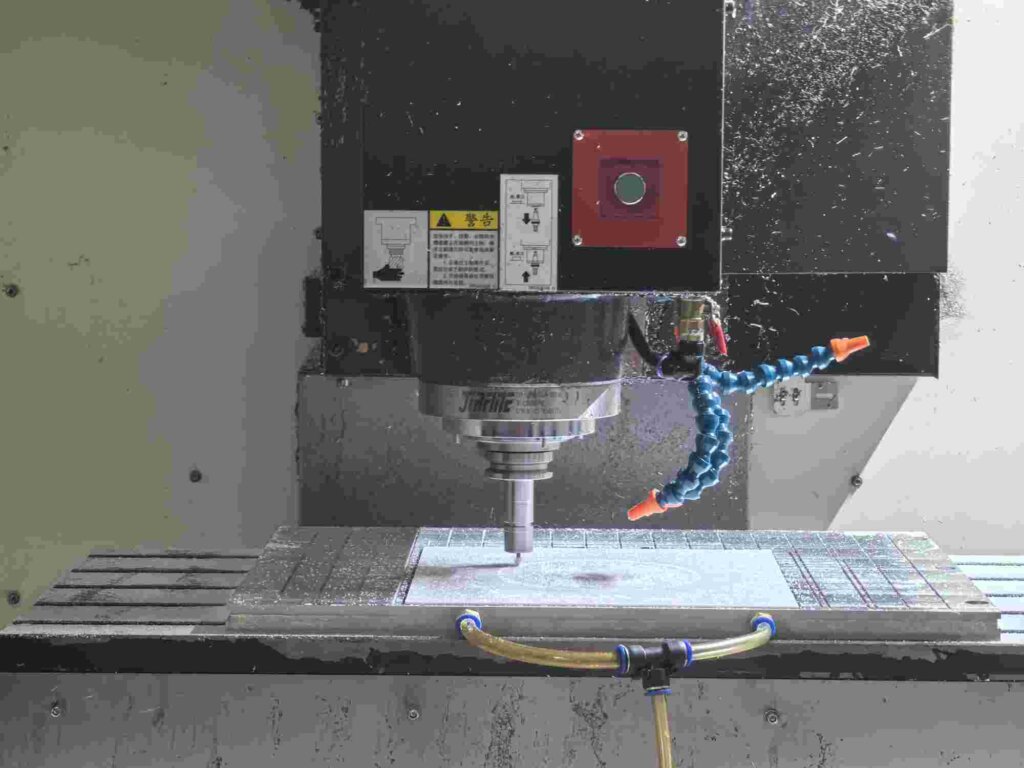

2. The Spindle

The spindle holds the cutting tool and rotates it at high speeds to remove material from the workpiece. In a 5-axis machine, the spindle can tilt and rotate, allowing it to reach areas that would be inaccessible to a 3-axis machine.

- Fun Fact: In high-performance 5-axis machines, spindle speeds can reach up to 30,000 RPM, allowing for ultra-smooth finishes.

3. The Worktable

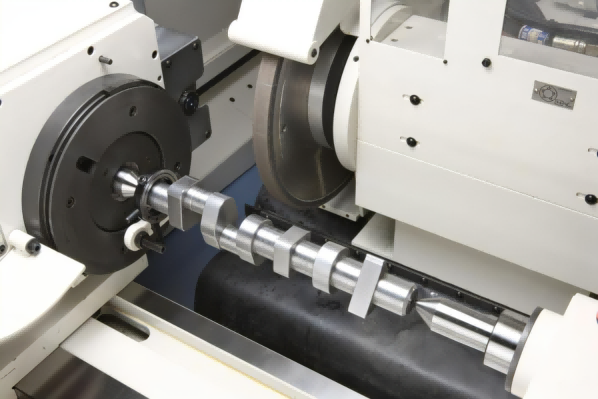

The worktable holds the workpiece and can move in multiple directions to position it under the cutting tool. Some 5-axis machines have a rotary table that can tilt and rotate, while others have a tilting spindle.

- Pro Tip: For precision work, the worktable can be adjusted to apply just the right amount of pressure, preventing the workpiece from moving during machining.

4. The Control Panel

The control panel is where the operator inputs the G-code instructions that tell the machine what to do. Modern control panels often feature touchscreens and intuitive interfaces, making them easier to use than ever before.

- Cool Feature: Some advanced panels include simulation software, allowing operators to visualize the machining process before starting. This can help catch potential issues before they become costly mistakes.

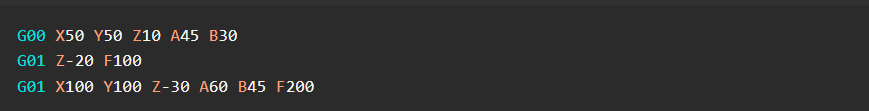

G-Code Example for 5-Axis Machining

Here’s an example of G-code for a 5-axis machining operation:

This code tells the machine to move to the coordinates (X50, Y50, Z10) with the A-axis at 45 degrees and the B-axis at 30 degrees, then perform a cutting operation at a feed rate of 100 mm/min.

Why Are 5-Axis CNC Machines So Important?

1. Complexity and Precision

5-axis machines are capable of creating parts with incredibly complex geometries, such as turbine blades, impellers, and medical implants. According to a 2022 report by Aerospace Manufacturing and Design, 5-axis machining has reduced error rates in aerospace component manufacturing by over 50%.

2. Efficiency and Speed

Because 5-axis machines can perform multiple operations in a single setup, they significantly reduce setup time and increase production speed. A 2021 study by Modern Machine Shop found that companies using 5-axis machines saw a 40% increase in production efficiency compared to 3-axis machines.

3. Cost-Effectiveness

While the initial investment in a 5-axis machine can be high, the long-term savings are substantial. By reducing material waste and labor costs, 5-axis machining can lower production expenses by up to 25%, according to a 2020 analysis by Manufacturing Global.

4. Versatility

5-axis machines can work with a wide range of materials, from lightweight aluminum to tough titanium. This makes them ideal for industries like aerospace, automotive, and medical devices, where material flexibility is key.

Real-World Applications of 5-Axis CNC Machines

1. Aerospace Industry

The aerospace sector relies heavily on 5-axis machines to create lightweight, high-strength parts like turbine blades, engine components, and fuselage frames. Boeing, for instance, uses 5-axis machines to manufacture components for its 787 Dreamliner.

2. Automotive Industry

Car manufacturers use 5-axis machines to create complex components like engine blocks, transmission cases, and suspension parts. Tesla, for example, uses 5-axis machines to produce high-precision components for its electric vehicles.

3. Medical Devices

5-axis machines are essential for developing surgical instruments, implants, and prosthetics. A 2023 case study by Medical Design & Outsourcing highlighted how a company used 5-axis machining to reduce the development time of a new prosthetic limb by 30%.

4. Consumer Electronics

From smartphones to wearables, 5-axis machines help electronics companies test and refine their designs. Apple, for example, uses 5-axis machines to perfect the fit and finish of its devices.

Challenges and Limitations

1. High Initial Cost

5-axis machines can be expensive, with prices ranging from $100,000 for basic models to over $1 million for advanced systems. However, many companies opt for outsourcing to reduce costs.

2. Skilled Labor Required

Operating a 5-axis machine requires specialized training. According to a 2021 article by IndustryWeek, there’s a growing skills gap in the manufacturing sector, with many companies struggling to find qualified CNC operators.

3. Material Waste

5-axis machining is a subtractive process, meaning it removes material to create the part. This can result in significant waste, especially for complex designs.

The Future of 5-Axis CNC Machines

The future of 5-axis CNC machines is looking bright, with several exciting trends on the horizon:

1. Hybrid Manufacturing

Combining 5-axis machining with additive manufacturing (3D printing) is becoming increasingly popular. Hybrid machines can 3D print a rough shape and then use 5-axis machining to achieve the final precision, offering the best of both worlds.

2. AI and Machine Learning

Artificial intelligence is being used to optimize 5-axis machining processes. A 2023 report by TechCrunch highlighted how AI algorithms can predict tool wear and adjust machining parameters in real-time, reducing downtime and improving accuracy.

3. Faster, Smarter Machines

Advances in CNC technology are making 5-axis machines faster, more precise, and easier to use. For example, new 5-axis CNC machines can create incredibly complex shapes in a fraction of the time.

Wrapping It Up

5-axis CNC machines are the ultimate tool for precision manufacturing, enabling the production of high-precision, complex components with unmatched efficiency. From aerospace to medical devices, these machines play a crucial role in shaping the world around us. While they come with challenges like high costs and the need for skilled labor, the benefits far outweigh the drawbacks.

If you’re considering investing in a 5-axis CNC machine, it’s important to weigh your options carefully. Look for a machine that meets your specific needs, whether it’s a basic 5-axis mill or a high-end multi-axis system. And don’t forget to factor in the cost of training your team to operate it effectively.

At the end of the day, a 5-axis CNC machine isn’t just a tool—it’s an investment in the future of your business. So, what will you create with it?

References

- Aerospace Manufacturing and Design (2022) – Report on 5-axis machining in aerospace.

- Modern Machine Shop (2021) – Study on production efficiency with 5-axis machines.

- Manufacturing Global (2020) – Analysis of cost savings with 5-axis machining.

- IndustryWeek (2021) – Article on the skills gap in CNC machining.

- TechCrunch (2023) – Report on AI in 5-axis machining.